Laminar and Turbulent Flow

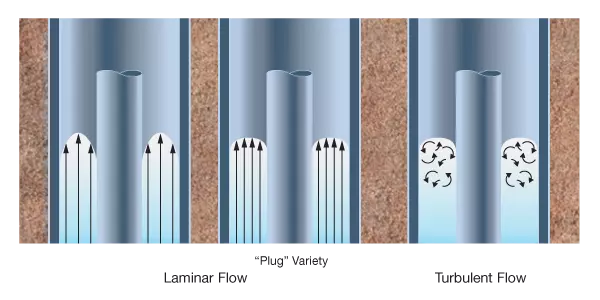

When a single-phase fluid flows below a certain rate through a pipe (or through the annulus between two pipes), the fluid particles flow in a single direction, across a line perpendicular to the pipe axis. The particles in the center of the pipe tend to move faster than those near the pipe wall, and there is no fluid motion transverse to the bulk flow direction. This condition is known as laminar flow. Plug flow describes a low-velocity, sub-laminar condition where a fluid moves uniformly as a homogeneous, relatively undisturbed body.

Under certain conditions, the fluid particles swirl around in all directions within the annular space. The speed of flow increases rapidly with the distance from the pipe wall and remains fairly constant throughout the main body of the moving fluid. This is known as turbulent flow.

The distinction between laminar and turbulent flow is described by a dimensionless term known as the Reynolds Number (NRe), which relates fluid density, velocity, viscosity and the diameter of the flow conduit.

For flow inside pipes, the Reynolds Number is expressed as

![]() (1)

(1)

For annular flow, the Reynolds Number is

![]() (2)

(2)

Where

![]() is the fluid density

is the fluid density

![]() is the fluid velocity

is the fluid velocity

D is the inside diameter of the pipe

D1 is the outside diameter of the pipe

D2 is the hole diameter or the inside diameter of the outer casing

μ is the fluid viscosity

In field units (![]() in

in ![]() ,

, ![]() in

in ![]() , D in inches and μ in cp), equations 1 and 2 become

, D in inches and μ in cp), equations 1 and 2 become

![]() (3)

(3)

![]() (4)

(4)

In general, Reynolds numbers of less than 2100 indicate laminar flow, while Reynolds numbers greater than 4000 indicate turbulent flow. Between these values, flow is considered transitional.

At low flow rates, fluids always flow in a laminar fashion and their flow behavior can be characterized by their viscosity. As flow rate increases, fluids transition to a turbulent flow regime, where the flow is less dependent on viscosity and more dependent on inertial forces.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.