Retarders

Retarders are used primarily to extend the time that a cement slurry can be pumped and displaced into position before it begins setting. For example, a retarder may be used in deep or very hot wells to prevent setting of the cement before it is properly placed in the annulus.

Setting time is a function of both temperature and pressure. Setting time can also be shortened if pumping is interrupted (loss of agitation accelerates setting). It is important to understand how these parameters are likely to change over the length of the wellbore before selecting specific retarders. If cement setting time is retarded too much it can lead to:

- Delays in resuming drilling operations

- Settling and separation of slurry components

- Formation of free-water pockets

- Loss of hydrostatic head and an influx of formation fluids into the slurry

Commonly-used Retarders

In general, organic materials will retard cement setting time. The most common retarders are lignosulfonates, primarily calcium lignosulfonate. Lignosulfonates are polymers derived from wood pulp. Calcium lignosulfonate is typically added in concentrations of 0.1% to 1.5% BWOC. Its effectiveness is limited in temperatures above 250 °F. When blended with sodium borate the temperature range can be extended to as high as 600 °F.

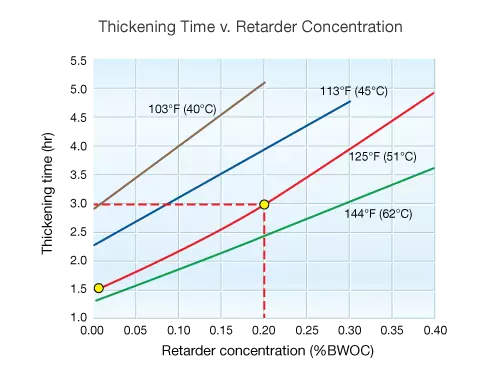

The effect of a lignosulfonate retarder on a 15.8 ![]() ) Class G cement is shown in Figure 1. At 125 °F the thickening time can be doubled, from 1.5 hours to 3 hours, with the addition of 0.20% BWOC of retarder.

) Class G cement is shown in Figure 1. At 125 °F the thickening time can be doubled, from 1.5 hours to 3 hours, with the addition of 0.20% BWOC of retarder.

Other retarders include carboxymethyl hydroxyethylcellulose or CMHEC (which also increases the viscosity of the slurry), organophosphates, and sodium chloride (only in high concentrations).

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.