Cement Additives in Drilling

Learning Objectives

After completing this topic “Cement Additives in Drilling“, you will be able to:

- List the key cement properties that are modified by additives.

- List the common categories of additives used in cementing operations.

- Summarize the functions and application of the common additives.

Introduction

“Neat” cement – that is, cement containing no additives – is seldom used in cementing jobs because it does not have the properties required either by the slurry, the set cement, or both. The Class G or H cement that is most commonly used can be tailored to meet most cementing job specifications with the use of additives.

A well designed cement system, consisting of basic cement plus additives, must:

- Remain pumpable until properly placed in the well.

- Set uniformly, bonding securely to both the casing and the formation.

- Achieve the necessary compressive strength within an allotted time period.

It must do these things under conditions that can vary from below freezing in arctic permafrost zones to near freezing in deepwater wells to 700 °F in geothermal wells. Pressures can range from ambient to more than 30,000 psi at the bottom of deep, overpressured wells. In addition, cements must be capable of performing consistently in spite of widely variable formation permeability, corrosive subsurface fluids, and variable hole conditions.

Most cement additives are free-flowing powders that are dry-blended with the cement prior to its transportation to the well. When necessary, some powdered additives can be dispersed in the mixing water at the site. Liquid additives are more commonly used offshore and in remote land locations where dry cement blending and storage are not as common.

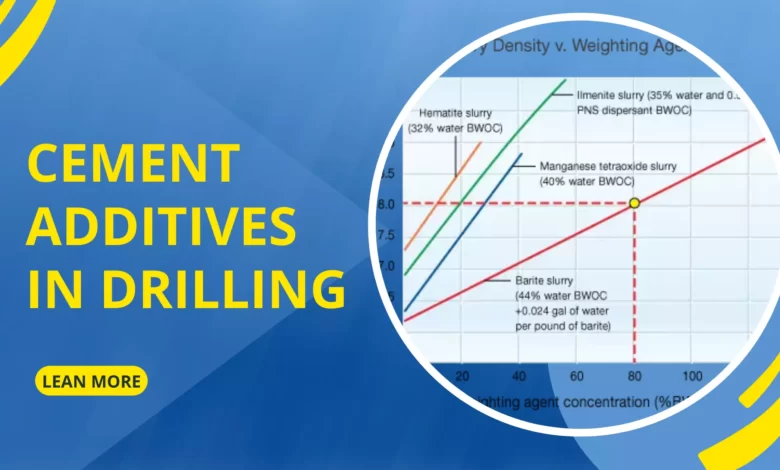

The key cement properties that are modified by additives are listed below:

| Cement slurry | Setting or thickening time (acceleration, retardation) Density (extenders, weight increase/reduction) Viscosity (thinners or thickeners) Fluid loss resistance (via filtrate loss) Lost-circulation resistance (via whole slurry loss) |

| Set cement | Compressive strength Strength retrogression (loss with time) Expansion/contraction |

The performance of additives is influenced by the chemical and physical properties of the basic cement, which can sometimes vary even within an API/ISO classification. Other variables can also influence additive performance:

- Mixing temperature and pressure

- Additive concentration

- Mixing method

- Additive mixing order

- Water-to-cement ratio

As a result, practical cement system design involves thorough laboratory testing before the job, using representative samples of the cement and mix water to be used on site. Also important is an understanding of the expected transport and storage conditions for both bulk cement and additives.

This subtopic discusses each of the major categories of cement additives, their impact on cement properties, and examples of the most common additive choices.