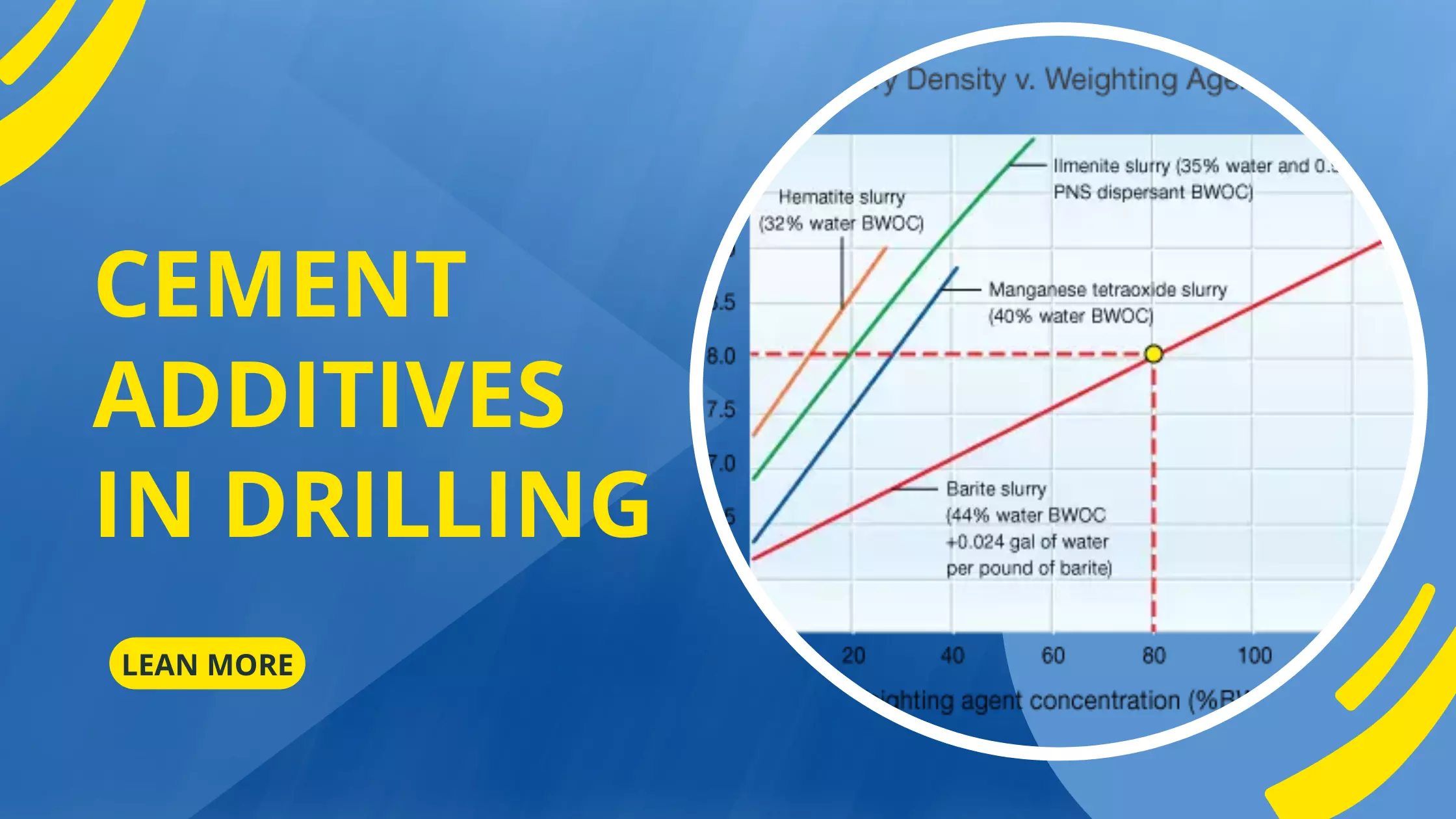

Learning Objectives After completing this topic “Cement Additives in Drilling“, you will be able to: List the key cement properties that are modified by additives.List the common categories of additives used in cementing operations.Summarize the functions and application of the common additives. Introduction https://youtu.be/u2pl5-yaExI “Neat” cement – that is, cement …

Read More »Chemistry and Classification of Oil well Cements

Learning Objectives After completing this topic “Chemistry and Classification of Oil well Cements“, you will be able to: List API cement classes and their application.Describe the mixing quantities and procedures for various classes of cement and how they relate to cement job planning and execution. Introduction https://youtu.be/D2QVAbm1Nfs Chemistry and Classification …

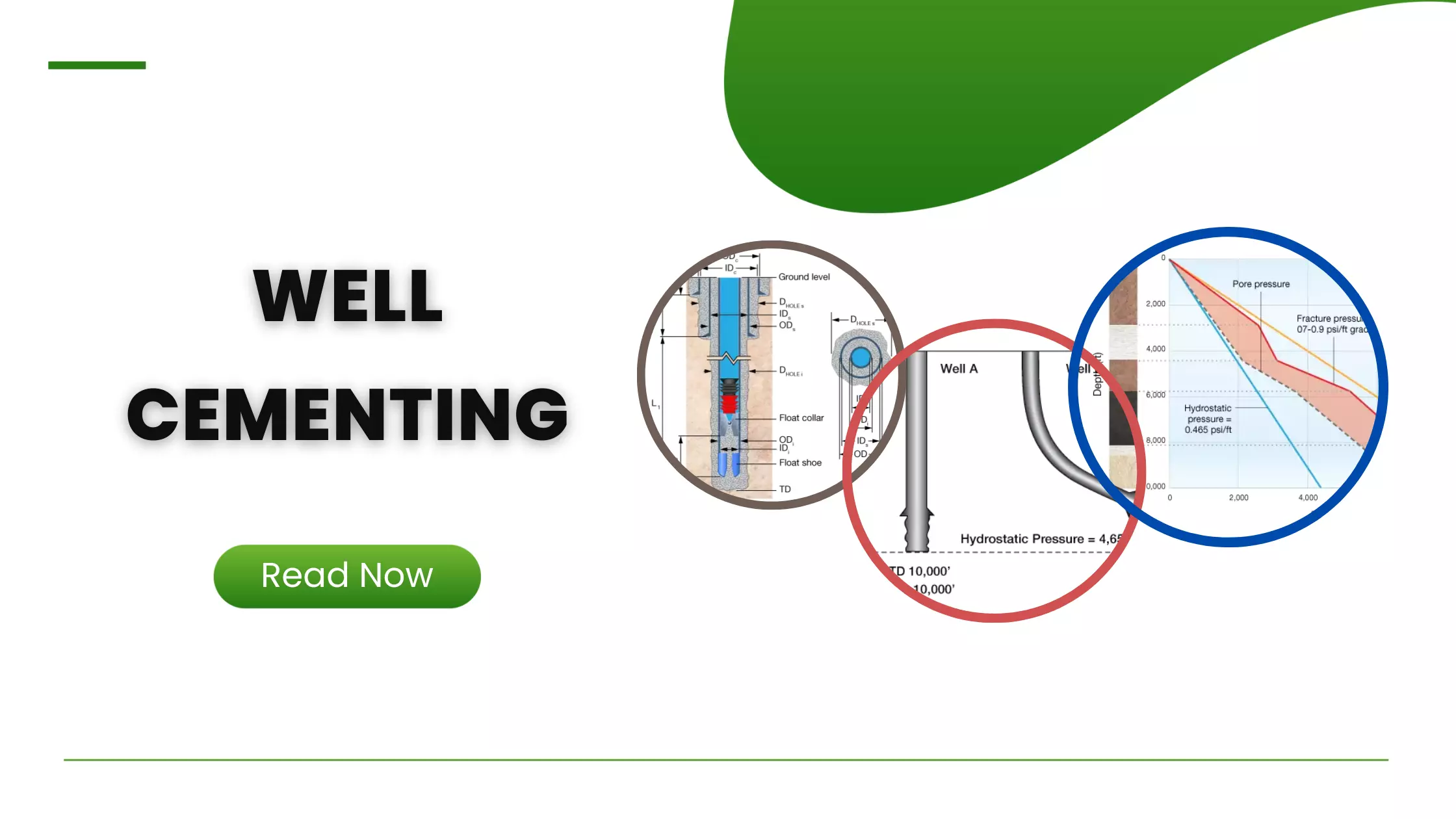

Read More »Introduction to Well Cementing

After completing this topic "Well Cementing", you will be able to: - Describe the evolution of cementing methods and the role of ...

Read More »Case Studies Underbalanced Drilling

Underbalanced Drilling using Coiled Tubing Drilling Scenario An operator in the Michigan Basin of the United States desired to deepen a well producing from a Niagaran Reef carbonate reservoir. Conventional drilling techniques were not previously successful, because of the overpressure conditions present in this interval. The feasibility study performed by …

Read More »Underbalanced Drilling: General Issues

Coiled Tubing for Underbalanced Drilling Coiled tubing is ideally suited for drilling underbalanced. The continuous nature of the coiled tubing string and the exclusive use of a mud motor for drilling provides several advantages over conventional jointed pipe drilling for underbalanced applications: Drilling with a mud motor prevents the formation …

Read More »Snub Drilling

Snub Drilling Overview If very high formation pressures and uncontrollable loss of circulation are expected during underbalanced drilling, use of a snubbing or a coiled tubing (CT) unit may be necessary. This type of underbalanced drilling is known as snub drilling. Snub drilling should be considered for wells with: Very high …

Read More »Flow Drilling

Flow drilling was first developed for the Austin chalk reservoirs in Texas. Underbalanced conditions are created using

Read More »Gasified Liquids

Gasified liquids, which are used for underbalanced drilling applications, generally do not contain surfactants. Bottomhole pressures are ...

Read More »Stiff Foam Drilling

Stiff Foam Drilling Overview Stiff foam is a more viscous and stable form of foam that can be generated using surfactants alone. The reduction in horsepower requirements and low water consumption make the stiff foam a more economical option compared to other drilling fluids. In general, stiff foam drilling involves …

Read More »Foam Drilling | What is Foam Drilling?

Foam drilling is a drilling technique that involves the use of a polymer foaming agent, water, and compressed air. In certain areas, it’s more effective than mud drilling, and it generally results in more efficient spoil disposal. Trenchless operators have access to a variety of drilling techniques. Foam Drilling Overview …

Read More » Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.