Flow Drilling Overview

Flow drilling was first developed for the Austin chalk reservoirs in Texas. Underbalanced conditions are created using liquid-only drilling fluid, in contrast to the other techniques that use a gaseous phase. The term flow drilling, therefore, is only used for underbalanced applications where a permeable formation is intentionally drilled with a liquid drilling fluid that would allow the formation to flow during drilling. All well control is handled at the surface.

Since the wellbore pressure is much higher with a liquid drilling fluid, high-pressure formations can be drilled using flow drilling without reaching the limitations of the surface equipment. The daily operating costs are less compared to other gaseous underbalanced drilling techniques since there is no need of gas supply for drilling.

The wellbore pressure imposed by the fluid column and frictional losses must be less than the formation pore pressure to create underbalance while drilling. One way to achieve this is to use a drilling fluid with a density that is less than the pore pressure gradient of the formation.

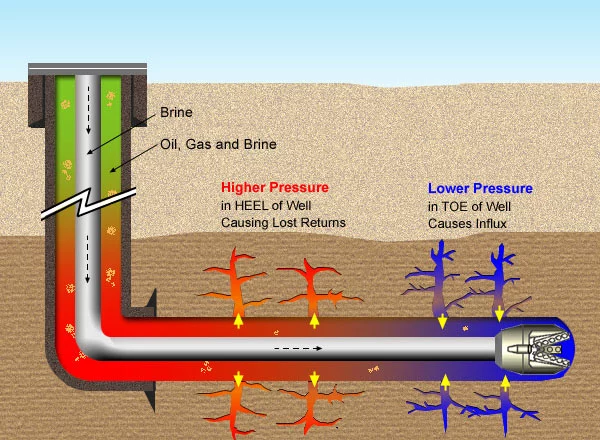

A number of reservoirs have pore pressure gradients large enough to establish underbalanced conditions when a liquid drilling fluid is used. It is also possible to establish underbalanced drilling in fractured formations even if the mud gradient is larger than the pore fluid gradient. In this case, lost circulation into fractured zones causes a reduction in the hydrostatic head that eventually leads to formation fluids flowing into the wellbore. Once the inflow occurs during underbalanced drilling, the process eventually will equalize the hydrostatic head and pore pressure. (Figure 1)

While selecting a drilling fluid, the density must be chosen such that the wellbore pressures would be less than the maximum formation pressure and more than the minimum stability criterion.

The main motivation behind underbalanced drilling is to avoid formation damage. However, one has to keep in mind that it is not always possible to maintain the desired underbalance at the sandface. Therefore, it is a better practice to use less damaging, clean liquids as the flow-drilling fluid.

Since many viscosifying agents cause emulsions in the presence of hydrocarbons, they should be avoided if possible. Generally higher viscosities are needed in deviated and horizontal well drilling to obtain adequate hole cleaning.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.