Completion Applications: Fracturing Horizontal Wells

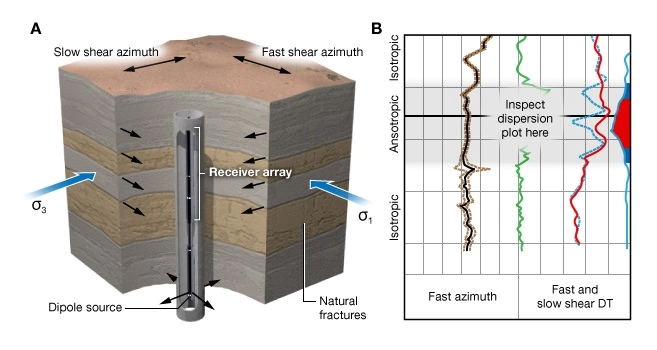

Shale gas production is achieved by hydraulic fracturing of horizontal wells. Reservoir optimization decisions require knowledge of the stress profile and stress direction before the horizontal well is drilled. This calls for careful planning, data acquisition, and fracture design. Key geomechanics information needed to support fracture stimulation of horizontal wells includes:

- A vertical profile of

- Direction of the principal axes of stress

- A profile of pore pressure

- Evaluation of elastic anisotropy

- Determination of the static elastic moduli (isotropic and anisotropic)

- Evaluation of lateral variability in the geomechanical parameters

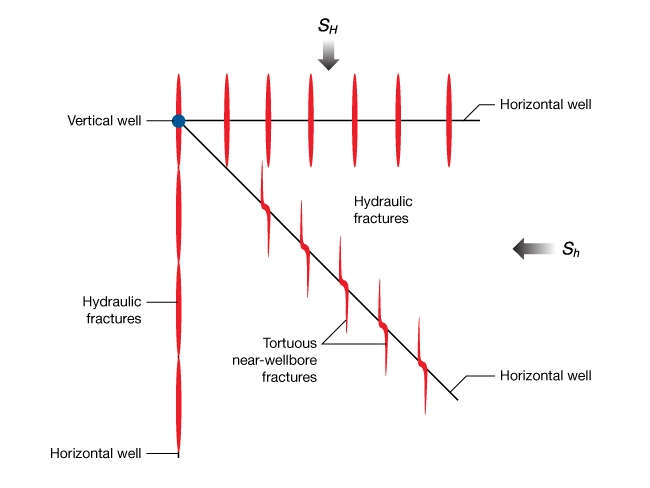

Effective reservoir stimulation is achieved when horizontal wells are drilled in the directions of the principal horizontal stresses, ![]() or

or ![]() . Fractures initiated from a well drilled at the azimuth of

. Fractures initiated from a well drilled at the azimuth of ![]() propagate perpendicular to the well axis. In principle, multiple fracturing stages result in multiple parallel fractures. Fractures initiated from wells aligned with

propagate perpendicular to the well axis. In principle, multiple fracturing stages result in multiple parallel fractures. Fractures initiated from wells aligned with ![]() , propagate along the axis of the well. Depending on how the job is conducted, there could be one long fracture or multiple short fractures aligned with the wellbore. Fractures initiated from wells misaligned with either principal horizontal stress do not propagate as simple planar fractures. They tend to form a complex network of curvi-planar fractures near the wellbore leading to high breakdown pressures, poor proppant placement, and ineffective reservoir stimulations as illustrated in Figure 1.

, propagate along the axis of the well. Depending on how the job is conducted, there could be one long fracture or multiple short fractures aligned with the wellbore. Fractures initiated from wells misaligned with either principal horizontal stress do not propagate as simple planar fractures. They tend to form a complex network of curvi-planar fractures near the wellbore leading to high breakdown pressures, poor proppant placement, and ineffective reservoir stimulations as illustrated in Figure 1.

Away from the well, all fractures propagate in a vertical plane perpendicular to ![]() . Shear stresses acting on wells misaligned with the principal stress result in high breakdown pressures, tortuous fractures near the wellbore, and unfavorable reservoir stimulation.

. Shear stresses acting on wells misaligned with the principal stress result in high breakdown pressures, tortuous fractures near the wellbore, and unfavorable reservoir stimulation.

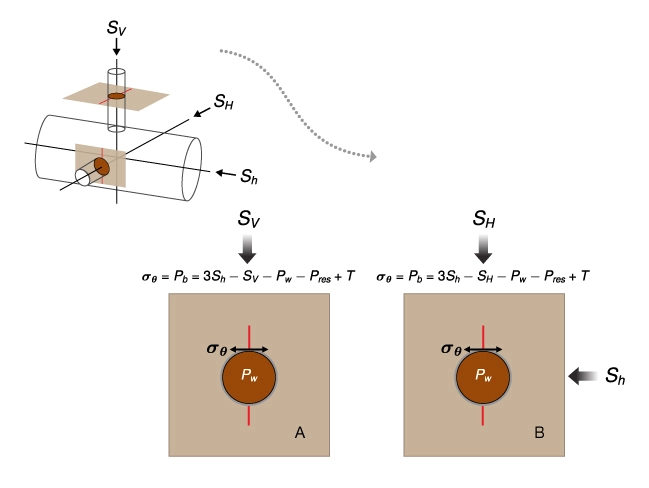

Most horizontal wells are stimulated from cased-hole completions. This completion option provides greater control of where fluids are injected and, to some extent, fracture geometry by selecting the location and orientation of perforations. Figure 2 shows idealized stresses around perforations shot from a horizontal well drilled at the azimuth of ![]() . As the red lines indicate, fractures initiated from horizontal and vertical perforations may be coplanar if the perforations are coplanar. If the well is drilled in the direction of

. As the red lines indicate, fractures initiated from horizontal and vertical perforations may be coplanar if the perforations are coplanar. If the well is drilled in the direction of ![]() , perforating only in the vertical plane would promote fractures that propagate along the well axis.

, perforating only in the vertical plane would promote fractures that propagate along the well axis.

Complications with this idealized description of fracture stimulation may be caused by natural fractures, lateral variability of reservoir stress and elastic properties. In addition, closely spaced hydraulic fractures perturb the in-situ stress field affecting fracture propagation path and reservoir productivity. While the influence of natural fractures can be recognized by microseismic monitoring, the lateral variability is determined by logging horizontal wells.

Fracturing for Sand Control

Deepwater reservoirs typically are poorly consolidated and require solids exclusion using gravel-packing or fracture-packing. A dimensionless value that compares production efficiency to actual conditions is known as skin. Gravel packing is the most common method, although it can result in skin factors of 20 or more indicating significant flow impairment (Figure 3). A frac-pack is a hydraulic fracturing operation conducted in weak, high-porosity reservoirs. In this operation, gravel is pumped down the annulus, between the wellbore and a screen, at pressures above the fracture pressure. Compared with high-strength, low-permeability reservoirs, these fractures are shorter and wider. Fracture lengths are on the order of meters, versus hundreds of meters in hard rocks, and widths are inches versus fractions of an inch. Negative skin factors for frac-pack completions indicate improvement of the near wellbore flow conditions compared with virgin reservoir flow conditions.

The inputs to a frac-pack design are the same as for hard rock stimulations. As with hard rock, the profile of ![]() governs fracture height and Young’s modulus controls fracture width. In contrast to hard rock applications, the difference between the static and dynamic elastic modulus is very high so it is particularly important to correct moduli derived from geophysical logs for this effect. Knowledge of stress direction is used to orient perforations.

governs fracture height and Young’s modulus controls fracture width. In contrast to hard rock applications, the difference between the static and dynamic elastic modulus is very high so it is particularly important to correct moduli derived from geophysical logs for this effect. Knowledge of stress direction is used to orient perforations.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.