Learning Objectives

After completing this topic ” Squeeze Cementing “, you will be able to:

- List the reasons for remedial cementing.

- Define squeeze cementing and associated terms.

- Summarize the major considerations involved in planning a squeeze cement job.

- Summarize the basic principles of squeeze cementing and identify common misconceptions about how a squeeze cement job works.

- Describe high-pressure and low-pressure squeeze methods and list the benefits, limitations, and areas of application.

- Describe alternative methods for placing a cement squeeze.

- List methods for evaluating the success or failure of a cement squeeze.

- State factors that can cause a squeeze cementing job to fail.

Introduction Squeeze Cementing

The term remedial cementing encompasses any application of cement to repair well problems. These problems can occur at any time in the life of a well, from the drilling phase through the final abandonment phase. In some cases the problem that must be remedied is the result of a poor primary cement job. With remedial cementing, relatively small volumes of cement are circulated downhole via tubing or drill pipe. This is unlike primary cementing, where relatively large volumes of cement are circulated downhole through the casing being cemented.

There are two broad categories of remedial cementing: squeeze cementing and plug cementing. Squeeze cementing uses pump pressure to squeeze cement through an opening to fill a void. Plug cementing places cement within a wellbore or casing to prevent flow. This course focuses on squeeze cementing.

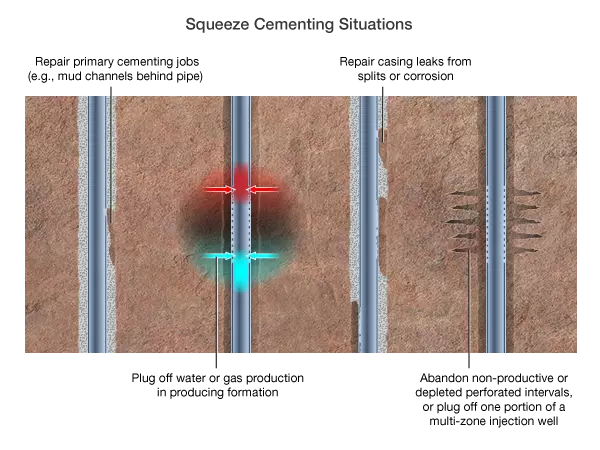

The most common applications of squeeze cementing (Figure 1) include:

- Repairing primary cementing jobs such as mud channels left behind pipe, annular areas with insufficient cement, or leaking liner tops

- Plugging off water or gas production from perforated intervals across a producing formation, or from nearby formations higher or lower in the wellbore

- Repairing casing leaks from split or corroded casing

- Abandoning non-productive or depleted perforated intervals, or plugging off one portion of a multi-zone injection well

During most squeeze cementing operations, the particles in the cement slurry being too large to enter the formation matrix – form a filter cake on the borehole wall and in perforation tunnels. Only the liquid portion of the cement slurry enters the formation as filtrate. The rate of filter cake formation is a function of the character of the cement slurry, the permeability of the rock formation, and the pressure being applied during the squeeze.

Mathematical models of this relationship are used to determine the appropriate level of pressure and period of time it should be applied to achieve a good squeeze. The objective of a good squeeze through a casing perforation is to fill the perforation tunnel with filter cake and leave only a small node of cement protruding inside the casing. The objective is to avoid having the cement bridge off within the casing before the filter cake has formed against the formation.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.