Volume Calculations

The starting point in designing a primary or remedial cementing job is to estimate the volumes of cement slurry and displacement fluid.

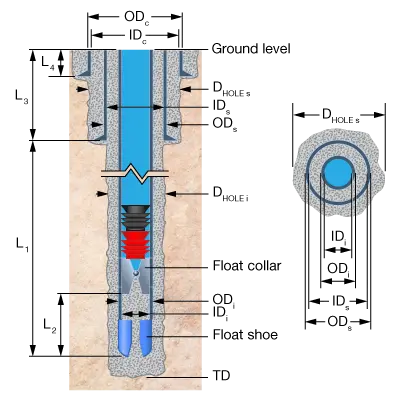

Figure 1 is a simplified well cross section showing the volumes under consideration in a typical primary casing cement job. The goals for this job are to:

- Fill the annular space between the casing and the formation with cement.

- Leave enough cement in and around the bottom of the casing to ensure the integrity of the cement bond.

In field calculations, the volumes represented in Figure 1 are obtained directly from such resources as the Halliburton Cementing Tables (e-Redbook) or the Schlumberger i-Handbook. In this discussion, the formulas are presented directly in order to show the basis of the numbers provided by these industry resources.

The theoretical volume of cement slurry needed to fill the annular space between the open hole formation and the outside of the casing (VAnnulus) is:

![]() in consistent units

in consistent units

When VAnnulus is given in ft3, Dhole and OD are given in inches, and L1 is given in feet, the relationship becomes:

![]()

A contingency or excess volume, expressed as a multiplier of the nominal hole volume, is often included in open hole volume calculations to account for borehole diameters that exceed the nominal bit diameter. This excess can be established based on local experience or determined from an open hole caliper log.

For example, if a 25 % contingency factor is applied then a multiplier of 1.25 is assigned to the annular volume equation:

![]()

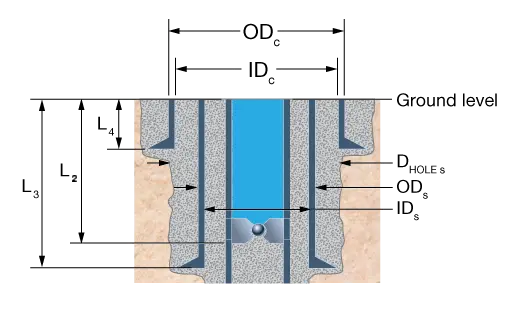

Surface casing is typically cemented to surface to avoid communication between well fluids and fresh water zones. Intermediate casing may also be cemented to surface, as shown in Figure 2, where surface casing has been cemented across the interval L1, and the subsequent string of intermediate casing has just been cemented across the interval (L1+L3).

For the intermediate casing of Figure 2, the volume of cement slurry needed to cement the string all the way to surface is a five-part calculation:

1. Volume of casing/open hole annulus (VAnnulus-1):

![]()

Where Dhole and ODi are, respectively, the intermediate hole diameter and casing outside diameter in inches. L1 is the distance between the surface casing and intermediate casing depths.

2. Volume of casing/casing annulus (VAnnulus-2):

![]()

Where IDS is the inside diameter of the surface casing in inches (note that there is no excess applied, because the ID of the casing is known), and L3 is the surface casing depth.

3. Volume of cement in ft3 left inside the casing (Vcsg):

![]()

Where L2 is the distance, in ft, from the float collar to the casing shoe.

4. Volume of cement in open hole below casing (VOH):

![]()

Where TD is the total depth in feet.

5. Total cement volume required (Vcmt = VAnnulus– 1 + VAnnulus−2 + Vcsg + VOH):

![]()

The volume of post-flush fluid needed to displace the cement slurry (Vdispl) to the top of the interval is:

![]()

Calculation Example:

In this worked example, the surface casing of the assignment well (Figure 3) is being cemented. The calculations to estimate the volume of cement slurry and post-flush fluid required to displace the cement are shown. A contingent cement volume of 20% is included.

Conductor casing:

- ODc=20 in

- IDc=19.0 in

- L4=80 ft

Surface string of casing:

- Dhole=17.5 in

- ODs=13.375 in

- IDs=12.615 in

- L2 (float collar depth) = 1465 ft

- L3=1505 ft

- TD=1510 ft

Use a 20 percent excess, which will incorporate the open hole volume below the casing shoe.

Equations to apply:

![]()

![]()

![]()

![]()

![]()

![]()

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.