Cement Evaluation | Cement Evaluation Well Logging: Assessing Cement Integrity in Oil and Gas Wells

Learning Objectives

After completing this topic “Cement Evaluation”, you will be able to:

- Summarize methods for evaluating quality of a cement bond.

- Describe the use of production logging and testing in determining cement bond quality.

- Describe the use of cased hole logging tools in determining cement bond quality.

Imagine a scenario where you invest millions of dollars in drilling an oil or gas well, only to discover that the cement used to seal the wellbore is defective. This can lead to catastrophic consequences, such as well integrity issues, production losses, and costly remediation operations. To mitigate these risks, the oil and gas industry relies on a crucial technique called cement evaluation well logging. In this article, we will explore the principles, applications, challenges, and future trends of cement evaluation well logging.

Introduction To Cement Evaluation

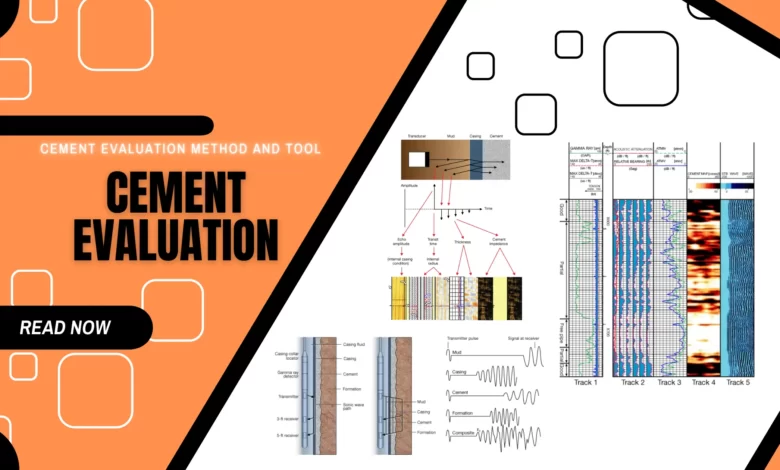

Cement evaluation well logging is a process that involves assessing the quality and integrity of the cement used in well construction. It provides valuable insights into the bonding between the casing and the formation, ensuring zonal isolation and preventing fluid migration. By utilizing various logging tools and techniques, engineers can evaluate the cement’s properties, such as bond strength, thickness, and homogeneity.

A primary cement job must be evaluated to determine the quality of the bond between casing and cement and cement and formation. Reasons for a poor bond might include:

- The casing-borehole or casing-casing annulus has not been filled with cement to an acceptable height

- The cement seal at the casing shoe or at the top of a liner is not strong enough to prevent hydraulic communication

- Specific formations are not isolated from one another due to channels or a micro-annulus behind the casing

If any of these problems are detected, remedial squeeze cementing operations are usually required.

Common cement evaluation techniques include:

- Pressure and inflow tests

- Logging surveys including acoustic cement bond logging and ultrasonic evaluation

Less frequently used methods include:

- Temperature surveys

- Radioactive tracer logs

Pressure or Inflow Tests

Following the primary cement job, after the cement has set and the casing shoe is drilled out, a positive pressure test is performed to test casing integrity. This is often called a leak-off test or pressure integrity test. The test involves increasing the internal pressure in the casing to ensure that it can support the higher pressure to be encountered during subsequent drilling. If the casing does not hold pressure, it indicates a poor cement job and the interval around the bottom of the casing will need to be squeezed.

Similarly, a negative pressure test can be performed to determine if fluid is flowing into the well bore. This is called an inflow test and often involves the use of drill string test (DST) equipment, in which a packer is set and the pressure inside the drill string is reduced. If flow is possible from a formation behind pipe through the casing shoe due to a poor cement job, the DST pressure gauge will record a change in pressure accompanying the inflow. A total lack of flow indicates a competent casing shoe.