Assignment Primary Cementing

Cement Job Design:

Part A:

For the production string of the Assignment well, it has been determined that the pressure required to pump the slurry up the annulus (Annular Pressure Loss) is 550 psi.

You are using a Class G cement containing fly ash (density 14.5 ppg) at 8,000 ft TVD. The fracture pressure is 0.8 ![]() .

.

What is the maximum allowable pump pressure to push the slurry up the annulus without fracturing the formation?

Part B:

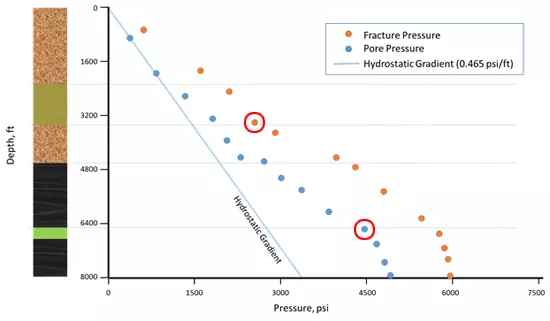

You are designing the mud weight for the production string of the Assignment well, and you are given the following pressure chart for the well.

The casing string goes to 8000 TVD, and you are given the task of designing the job. Assume a negligible annular pressure loss.

1) Can this job be pumped in a single stage, or are two stages required?

2) What cement weight(s) are acceptable for this job?

Solution

Part A Solution:

The fracture pressure of the well is ![]() .

.

The hydrostatic pressure of the slurry in the annulus is ![]() .

.

This means that the surface at the bottom of the well is 6032 psi greater than the surface when the fluid is not moving. When the fluid is moving, however, 550 psi of pressure is used to pump the slurry upwards. Therefore the downhole pressure is ![]() greater than the pump pressure.

greater than the pump pressure.

The maximum pressure allowed downhole is 6400 psi. Therefore the greatest pump pressure allowed is ![]() .

.

Part B Solution:

The greatest pore pressure gradient is at about 6400 ft, where the pressure is 4500 psi, or ![]() .

.

The lowest fracture pressure gradient is at about 3500 ft, where the pressure is about 2500, or ![]() .

.

It is therefore possible to pump this job as a single stage if the cement hydrostatic pressure is between 0.69 and 0.83 ![]() . Converting this to ppg:

. Converting this to ppg:

Minimum: ![]()

Maximum: ![]()

Neat cement or cement with a small amount of extender is acceptable for this job.

Assessment Primary Cementing

1. Which sequences can be followed for single-stage cementing? (Select all that apply.)

A .Pump wash, drop bottom plug, pump cement, drop top plug, displace cement with mud Correct

B .Drop bottom plug, pump cement, pump spacer, drop top plug, displace cement with mud

C .Drop bottom plug, pump spacer, pump cement, drop top plug, displace cement with mud Correct

D .Pump wash, drop bottom plug, pump spacer, pump cement, drop top plug, displace cement with mud Correct

2. Pumping excess cement slurry to ensure annular fill can cause __ if the borehole is closer to gauge than expected.

A .A drop in hydrostatic pressure

B .Fracture of the formation Correct

C .Zonal communication

3. When zonal isolation is particularly critical, what type of cement-filled casing packers can be utilized?

A .Inner

B .Circulating

C .External Correct

4. Challenges to getting a good primary cement job in the horizontal section of a Marcellus Shale well include __. (Select all that apply.)

A .drill cuttings Correct

B .fractures and faults Correct

C .doglegs Correct

D .high temperatures

E .washouts Correct

F .borehole cavings Correct

5. Casing programs are an integral element of the well planning and design process. In general, casing programs reflect a _ or _ process. (Select all that apply.)

A .top-down

B .outside-in

C .inside-out Correct

D .bottom-up Correct

6. What is required of a well–planned and executed cement job? (Select all that apply.)

A .The wellbore is drilled true to gauge. Correct

B .Recovery processes are pre-designed.

C .Quality control procedures are followed. Correct

D .The cement slurry design is tested in the laboratory. Correct

E .A densified cement is used.

7. Due to smaller annular spaces, mud cake and gelled mud removal can be particularly difficult in what cementing method?

A .Multiple-stage

B .Single-stage

C .Liner Correct

8. There are a number of challenges in cementing subsea wells, particularly those in deep water. These include: (Select all that apply.)

A .The high temperatures at the seafloor and within the deeper subsurface formations and the impact on cement slurry characteristics

B .The presence of relatively shallow water-producing or gas-producing zones that must be cemented quickly and effectively Correct

C .The added hydrostatic pressure from the additional distance above the subsea assembly and the smaller degree of separation between pore pressure and fracture pressure Correct

D .The complications introduced by the extended reach or horizontal wellbores commonly employed to develop offshore reservoirs from single subsea well templates Correct

9. Identify the special challenges of cementing horizontal intervals. (Select all that apply.)

A .Formation of free-water phase in cement slurry on high side of annulus Correct

B .Impact of decreased drag within the horizontal interval on hole conditions

C .Controlling the U-Tube effect

D .Maintaining borehole stability during cementing Correct

E .Cleaning of the low side of the borehole of both cuttings and mud Correct

10. Due to the development of low density-high-strength cements, which type of primary cementing is least likely to be part of a well’s cementing program?

A .Single-stage cementing

B .Multi-stage cementing Correct

C .Liner cementing

11. Multiple-stage cementing is uncommon today due to __.

A .targeting of deeper reservoirs where fracture gradients are much higher

B .development of high-strength, low-density cement formulations Correct

C .improved, higher strength casing

Recommended for You

Introduction to Well Cementing

Chemistry and Classification of Oil well Cements

Cement Slurry Flow Properties and Mud Displacement

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.