This topic covers the underbalanced drilling method, which is defined as the practice of drilling a well with the wellbore fluid gradient less than the natural formation gradient. Besides minimizing lost circulation and increasing the penetration rate, this technique has a widely recognized benefit of minimizing the damage caused by invasion of drilling fluid into the formation. Different underbalanced drilling equipment and techniques are discussed under this topic. The underbalanced well classification system used by the industry and several case studies are also covered in this topic.

Introduction

Conventional drilling practice calls for maintaining the hydrostatic pressure of the drilling fluid between the formation’s pore pressure and its fracture pressure. The drilling fluid is continuously circulated within the wellbore to control the formation fluids and transport cuttings to the surface. It also works as a stabilizing agent within the wellbore, and lubricates and cools the drill bit. The fluid is either a water-based or oil-based liquid that varies from 7.8 to 19 pounds per gallon, and contains a variety of solid and liquid products to impart density, fluid loss characteristics and rheological properties.

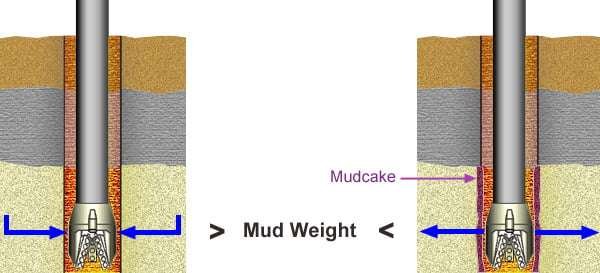

The conventional practice described above has long been recognized as the safest method for drilling a well. It does, however, have drawbacks. Since the drilling fluid pressure is higher than the natural formation pressure, fluid invasion frequently occurs, causing permeability damage to the formation. This damage is mainly caused by washout or physical blockage by the intrusion of fluids and/or solids into the formation structure.

Underbalanced drilling (UBD) is defined as the practice of drilling a well with the wellbore fluid gradient less than the natural formation gradient. It differs from conventional drilling in that the bottomhole circulating pressure is lower than the formation pressure, thereby permitting the well to flow while drilling proceeds (Figure 1).

Besides minimizing lost circulation and increasing the penetration rate, this technique has a widely recognized benefit of minimizing the damage caused by invasion of drilling fluid into the formation. In many UBD applications, additional benefits are seen due to reduction in drilling time, increased bit life, and early detection and dynamic testing of productive intervals while drilling. It is critical to keep the well underbalanced at all times, if formation damage is to be minimized.

Underbalanced drilling technology is a valuable method for minimizing formation invasion related problems. Because the majority of hydrocarbons today are found in existing fields with depleting pressures, or in complex and low quality reservoirs, the economical use of UBD becomes more and more popular.

Most of the underbalanced drilling applications today are conducted through the use of coiled tubing systems. Forty percent of all the onshore wells drilled in the year 2000 were conducted through underbalanced conditions. Joint industry projects currently underway off the coast of Brazil will likely change the conventional drilling practices in offshore applications.

“Underbalanced drilling technology can save the industry millions of dollars by increasing the amount of recoverable oil within a shorter time frame”.

History of Underbalanced Drilling

The concept of drilling with low pressure circulating fluid was first patented in the United States in 1866. Early applications used compressed air to drill the hole. As the technology evolved over the years, gas internal systems with stable foams and aerated fluids were introduced for specific drilling conditions

The technique called flow drilling was first developed in South Texas, and became very popular worldwide with early successful applications in Southern Canada, Australia and China. It was primarily used for re-development of fields where depleted pressure was an important concern.

During the 1990’s, underbalanced drilling was successfully applied in onshore and offshore drilling operations throughout Europe.

Early techniques developed by Angel (1957) and, Moore and Cole (1965) tried to predict the volume of air or gas required to adequately clean the air-drilled hole. There were also several attempts published in the literature to develop a systematic design procedure for estimating wellbore hydraulics in underbalanced drilling applications.

Currently, underbalanced drilling is the most exciting development in the area of drilling engineering.

Together with horizontal and multi-lateral drilling techniques, it holds tremendous value for drilling more cost-effective wells.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.