Directional Drilling Applications

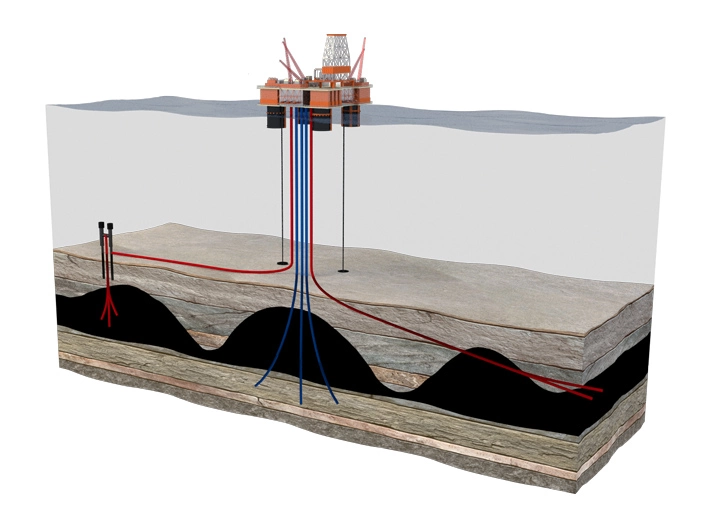

The earliest and still the most widespread application of controlled directional drilling is offshore development, where cost, logistical and environmental considerations make it essential to be able to drill multiple wells from a single surface location Figure 1). Arctic environments and urban settings are other areas in which this capability is essential to project success.

Other common applications of controlled directional drilling include:

- Reaching otherwise inaccessible locations: Reservoirs often underlie mountainous terrain, urban developments or other surface obstacles where building a rig location and drilling vertically to target would be impractical.

- Offsetting wells from the target location to take advantage of natural wellbore deviation tendencies: Certain formations have well-defined drilling characteristics, such as the well-known tendency for bits to “walk updip.” If we are aware of these characteristics, we can minimize drilling costs by offsetting the surface location and letting the bit drift to target.

- Fault drilling: Directional drilling can be used to direct a well course so that it is parallel or perpendicular to a fault plane, thus avoiding problems associated with trajectory control, borehole instability and the effects of formation pressure along fault planes.

- Salt domes: Directional drilling is a means of reaching reservoirs that underlie overhanging salt domes. By “drilling around” the salt, problems such as hole washouts, mud losses and corrosion may be avoided.

- Redrills or re-entries: Redrilling or re-entering from an existing wellbore is often an economical way of exploring for new producing horizons, or putting new life into old fields. Although redrills and re-entries are nothing new in the oilfield, their importance has grown over the years due to improvements in slim hole drilling and coiled tubing capabilities.

- Sidetracking or straightening: Directional drilling methods can be applied to remedial work. For example, it may be more practical to sidetrack around a stuck tool or other wellbore obstruction than to perform an expensive and possibly unsuccessful fishing job. Directional methods can also be used to straighten a crooked hole.

- Relief well drilling: Directional drilling is a valuable tertiary well control tool. When a blowout occurs and surface control methods are impractical, an alternative is to drill a relief well and pump kill fluids directly or indirectly into the blowout well’s annulus.

- Drilling under riverbeds: Drilling beneath riverbeds for pipeline installation is another common application of directional drilling methods.

Horizontal Drilling

Horizontal drilling is a special application of directional drilling, which involves directing a well laterally through a productive interval. In certain types of reservoirs (e.g., thin formations with good vertical permeability and tendencies toward drawdown-related problems such as water or gas coning), horizontal wells are a proven means of:

- increasing formation exposure Figure 2: Increased reservoir exposure due to horizontal drilling)

- improving well deliverability

- eliminating water and gas coning

- reducing overall development costs

Multilateral Drilling

Multilateral drilling involves drilling multiple wellbores from a single vertical or horizontal “trunk,” thus making it possible to intersect multiple geologic units from a single surface wellbore Figure 3). As is the case with single horizontal wells, their applicability is based on geological and reservoir characteristics.

Benefits directional drilling

Directional drilling, this technique is used in the oil and gas industry to access hydrocarbon reserves that are difficult to reach using conventional vertical drilling methods. Here are some benefits of directional drilling:

- Accessing hard-to-reach resources: Directional drilling allows operators to reach hydrocarbon reserves that are located beneath sensitive areas or reservoirs that cannot be easily accessed using vertical drilling methods.

- Reduced environmental impact: Directional drilling can be used to access oil and gas reserves located beneath urban areas, wetlands, or other sensitive areas without disturbing the environment on the surface.

- Increased productivity: By accessing multiple zones of the reservoir from a single wellbore, directional drilling can increase the productivity of a well and reduce the need for multiple drilling sites.

- Reduced cost: Directional drilling can be more cost-effective than traditional vertical drilling methods because it allows operators to access more resources from a single location.

- Improved safety: Directional drilling reduces the need for workers to be in dangerous locations, such as offshore drilling rigs, by allowing drilling to be done from a safe distance.

Disadvantages directional drilling

While directional drilling has many benefits, there are also some potential disadvantages to consider:

- Higher upfront costs: Directional drilling requires specialized equipment and skilled personnel, which can make it more expensive than conventional vertical drilling methods.

- Increased complexity: Directional drilling involves a more complex process than vertical drilling, which can increase the risk of equipment failure or wellbore instability.

- Longer drilling times: Directional drilling may take longer than vertical drilling due to the need to accurately steer the drill bit along the planned path.

- Technical challenges: Directional drilling requires precise planning and execution to ensure that the wellbore is drilled accurately and safely. This can present technical challenges that require experienced personnel and advanced technology.

- Environmental risks: While directional drilling can reduce surface disturbance and environmental impact, there is still a risk of groundwater contamination or other environmental damage if there is a wellbore failure or equipment malfunction.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.