Assignment

Basic Cement Slurry Formulation

Using the data provided, calculate the quantity of cement slurry and post-flush fluid required to cement the intermediate string of casing in the Assignment Well. Include a 25% cement contingency.

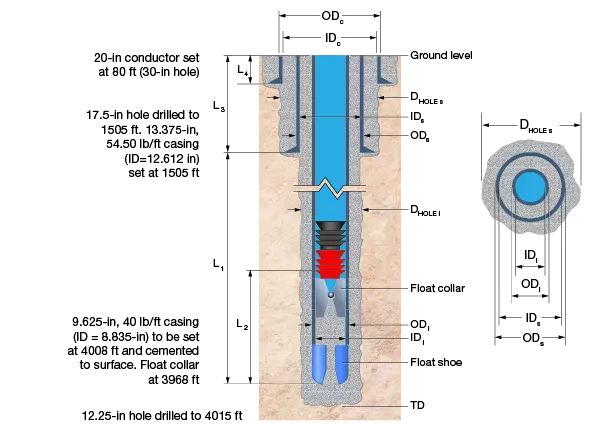

| Casing String | Hole Diameter Dhole (in) | Hole Depth* (feet) | Casing Shoe Depth* L (feet) | Depth to Float Collar* (feet) | Casing OD (in) | Casing ID (in) |

|---|---|---|---|---|---|---|

| Conductor [c] | 30 | 80 | L4=80 | N/A | 20 | 19 |

| Surface [s] | 17.5 | 1510 | L3=1505 | 1465 | 13.375 | 12.615 |

| Intermediate [i] | 12.25 | 4015 | 4008 | 3968 | 9.625 | 8.835 |

Summary Table

* All depths measured from Rotary Kelly Busing (RKB)

The fluid volume required to cement the intermediate string of casing of the Assignment well is 692 ft3 without contingency. Class H cement and water is being used for this job.

Part A:

Calculate the number of cement sacks needed, including a 25% contingency.

Part B:

Calculate the volume of mix water needed.

Solution

Part A Solution:

According to API Cement Slurry Specifications the yield for a Class H cement = ![]()

The cement needed for the intermediate string plus 25% of contingency = ![]()

Part B Solution:

According to API Cement Slurry Specifications the water/cement ratio for a Class H cement = ![]()

The amount of mix water needed = ![]()

Assessment

1. API cements are classified according to what oilwell conditions? (Select all that apply.)

A .Mix water

B .Additives

C .Pressure ✔

D .Depth ✔

E .Temperature ✔

Oilwell cements set and develop compressive strength as a result of ________.

A .pressure

B .aeration

C .dehydration

D .hydration ✔

How is a cement slurry mixture categorized if it contains no additives?

A .Common

B .Neat ✔

C .Portland

D .Ordinary

Water in excess of that required for cement to set is necessary for the formation of __________ that can be pumped.

A .a cement slurry ✔

B .aluminosilicates

C .interlocking crystalline structures

What is the recommended ratio of water to cement for mixing oilwell cement?

A .About 5.0 to 6.3 gallons per 94 lbm sack of dry cement, depending on the API Class ✔

B .About 2.8 to 7.3 gallons per 94 lbm sack of cement, depending on the API Class

C .About 4.0 to 5.3 gallons per 94 lbm sack of dry cement, depending on the API Class

Recommended for You

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.