Hole Cleaning Considerations

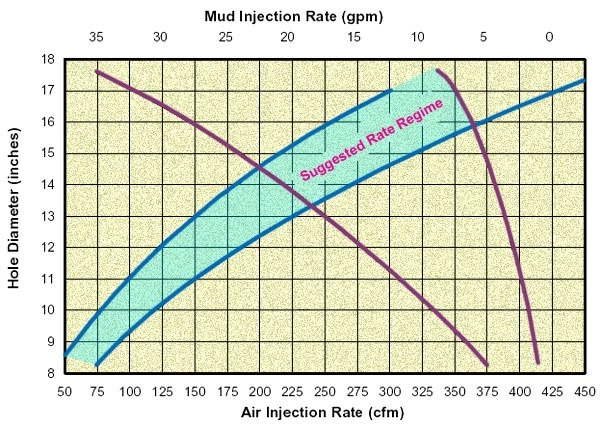

High viscosity makes it possible to use lower annular velocities while maintaining acceptable hole cleaning efficiency. Several models are available to simulate cuttings transport in stiff foams. The chart shown in Figure 1 was generated by Garavini et al. (1971). This chart is used to obtain proper air and liquid injection rates for stiff foam drilling as a function of hole size.

Surface foam qualities can be calculated using the air and liquid rates. Typically, stiff foam programs aim for surface foam qualities from 99 to 99.7 percent, and annular velocities in the range of 100 to 200 ft/min.

According to the field and laboratory data from stiff foam drilling operations, the injection rates can show a significant variation for sufficient hole cleaning. Even though the air and liquid injection rates are reduced in stiff foam drilling, the increased cost of consumables might increase the overall cost.

The circulating pressures in stiff foam drilling are not much different from those of regular foam. Because of its low density (caused by lower liquid volume fractions) stiff foam quality does not decrease rapidly. Therefore, it is not necessary to adjust the back-pressure in order to control the downhole foam quality.

Recommended for You Nitrogen Drilling

Stiff Foam Drilling Equipment

Due to lower injection rates, there is less need for air injection capacity. A typical operation will require no more than 205 to 300 psi delivery pressure and a maximum of 460 scfm injection capacity. For liquid injection, most soap pumps on an air/mist drilling rig should have sufficient capacity for typical stiff foam drilling jobs.

Different from conventional foam systems, a hopper system is usually required for an effective mixing of polymeric viscosifiers in water.

Stiff foams have a longer half-life than stable foams. If no additional defoaming processes are used, size of the reserve pit should be increased. Tests have to be conducted to determine expected half-life and effectiveness of the proposed defoaming procedures.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.