Assessment Hydraulic Fracturing Fluids

1. Which of these components would be used as a fluid loss additive in a hydraulic fracturing treatment?

A .Enzymes

B .Weak acids

C .Potassium chloride

D .Surfactants

E .Silica particles

2. The concentration of breaker used in a large fracture treatment is sometimes tapered so as to provide _________ viscosity stability in the leading portion and a ____________ break in the last volume of fluid pumped.

3. When a fracturing treatment consists of multiple slurry stages, the initial slurry stage typically has a proppant concentration that is ____________ those of subsequent stages.

4. At the end of the displacement stage of a fracturing treatment, what causes the bottomhole pressure to decline after the pumps are shut down?

A .Clearing of perforations

B .Leakoff of fluid into the formation

C .Packing of proppant in the fracture tip

D .Proppant settling

5. The settling velocity of a proppant particle is directly related to which of these quantities? (Select all that apply.)

A .Acceleration due to gravity

B .Density difference between proppant and fluid

C .Proppant diameter

D .Flow behavior index

E .Consistency index

6. Which of the following components might be included in a slickwater fracturing fluid? (Select all that apply.)

A .Corrosion inhibitors

B .Crosslinked gelling agents

C .Friction-reducing additives

D .Linear gelling agents

Frequently Asked Questions (FAQs)

1. What are the key factors influencing the choice of hydraulic fracturing fluids?

The choice of hydraulic fracturing fluids depends on several factors, including the geological characteristics of the formation, desired fracturing outcomes, and environmental considerations. Factors such as temperature, pressure, rock permeability, and the presence of certain minerals influence the selection of fluid additives and proppants.

2. Are hydraulic fracturing fluids harmful to human health?

The chemical additives in hydraulic fracturing fluids are subject to regulation and must meet safety standards. When used responsibly and in accordance with regulations, the risks to human health are minimized. However, improper handling or accidental spills can pose risks to both human health and the environment. Proper training, adherence to best practices, and robust safety protocols are crucial to prevent any adverse effects.

3. Can hydraulic fracturing fluids contaminate drinking water sources?

The risk of contamination primarily arises from faulty well construction, inadequate casing integrity, or poor handling of fluids at the surface. By implementing stringent well construction standards, proper cementing, and casing practices, the industry aims to prevent the migration of fluids into drinking water sources. Regular monitoring and testing of water quality help ensure the protection of drinking water supplies.

4. How are hydraulic fracturing fluids disposed of after the extraction process?

After the hydraulic fracturing process is complete, the fluid that returns to the surface, known as flowback fluid, is collected and managed. Depending on regulations and industry practices, flowback fluid can undergo treatment for reuse in future fracturing operations or be transported to a licensed disposal facility.

Treatment methods for flowback fluid may include filtration, chemical treatment, and removal of impurities before it can be reused. This helps minimize water usage and reduces the demand for freshwater resources. Alternatively, flowback fluid can be transported to underground injection wells that are specifically designed and regulated for the safe disposal of such fluids.

It is important to note that the proper disposal of flowback fluid is essential to prevent any potential environmental impacts. Stringent regulations and monitoring programs are in place to ensure the responsible management of hydraulic fracturing fluids throughout the entire lifecycle.

5. What are some alternative fluids being researched for hydraulic fracturing?

As the industry continues to evolve, researchers are exploring alternative fluids that offer potential advantages over traditional hydraulic fracturing fluids. These alternatives aim to address concerns such as water usage, environmental impact, and the need for chemical additives.

Some of the alternative fluids being studied include carbon dioxide (CO2), nitrogen foam, and gelled propane. These substances have different properties and may provide opportunities for more environmentally friendly and efficient fracturing processes. However, further research and testing are required to fully understand their feasibility and potential benefits.

6. What role does government regulation play in the use of hydraulic fracturing fluids?

Government regulation plays a crucial role in ensuring the safe and responsible use of hydraulic fracturing fluids. Regulatory bodies set standards and guidelines for well construction, fluid composition, wastewater management, emissions control, and other aspects related to hydraulic fracturing operations.

These regulations aim to protect the environment, public health, and safety while enabling the extraction of valuable resources. Compliance with regulations is essential for operators, and regular inspections and monitoring help ensure adherence to the set standards.

Assignment Hydraulic Fracturing Fluids

A fracturing fluid behaves according to a power law rheological model:

![]()

Where ![]() is the shear stress in units of Pa, and

is the shear stress in units of Pa, and ![]() is the shear rate in (

is the shear rate in ( ![]() ).

).

The value of ![]() is 1.05, and the value of

is 1.05, and the value of ![]() is 0.63.

is 0.63.

Answer the following questions:

- What is the equivalent Newtonian viscosity for (a) slot flow and (b) limiting elliptical flow? Assume for both cases that the average linear velocity (

) is 0.5 ft/s (0.1524 m/s) and the average cross-sectional width (

) is 0.5 ft/s (0.1524 m/s) and the average cross-sectional width ( ) is 0.2 in (0.00508 m).

) is 0.2 in (0.00508 m). - What is the settling velocity for each of the following proppants.

| Proppant | Largest dp, inches | Specific Gravity |

| 20/40 sand | 0.0331 | 2.65 |

| 12/20 ISP | 0.0661 | 3.15 |

| 20/40 bauxite | 0.0331 | 3.71 |

Solution

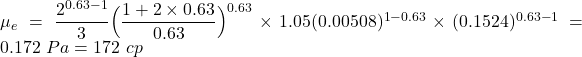

1. (a): For slot flow, the equivalent Newtonian viscosity is:

![]()

Where

![]() equivalent Newtonian viscosity

equivalent Newtonian viscosity

![]() flow behavior index = 0.63

flow behavior index = 0.63

![]() consistency index

consistency index

![]() average velocity

average velocity

![]() width of slot

width of slot

![]() maximum width of elliptical cross-section

maximum width of elliptical cross-section

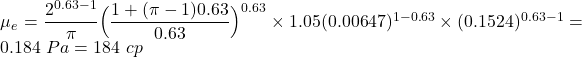

(b): For flow in a limiting elliptic cross section, the equivalent Newtonian viscosity is

![]()

Where ![]() maximum width of elliptical cross-section

maximum width of elliptical cross-section

The settling velocity (![]() ) is estimated as follows:

) is estimated as follows:

![]()

Where

![]() particle settling velocity

particle settling velocity

![]() proppant diameter

proppant diameter

![]() proppant density = specific gravity x 1000 kg/m3

proppant density = specific gravity x 1000 kg/m3

![]() fluid density = 1000 kg/m3

fluid density = 1000 kg/m3

![]() flow behavior index = 0.63

flow behavior index = 0.63

![]() consistency index = 1.05

consistency index = 1.05

![]() acceleration due to gravity = 9.8 m/s

acceleration due to gravity = 9.8 m/s

Substituting these numbers for each proppant results in the following:

| Proppant | Largest dp, in [m] | Specific Gravity | Vs ft/min [mm/s] |

|---|---|---|---|

| 20/40 sand | 0.0331 [.00084] | 2.65 | 0.098 [0.50] |

| 12/20 ISP | 0.0661 [0.0017] | 3.15 | 0.89 [4.1] |

| 20/40 bauxite | 0.0331 [0.0084] | 3.71 | 0.21 [1.1] |

Recommended for you

Hydraulic Fracturing Fundamentals

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.