Circulating Pressures

Circulating pressures can be estimated using multi-phase flow models. Depending on the type of injected liquid and the formation fluid inflow, there might be several phases present at a time. Four flow regimes are identified in gas-liquid flow:

- Bubble

- Slug

- Churn

- Annular

Density of the gasified liquid changes as the mixture flows up the annulus. Increasing flow rate causes an increase in the pressure losses in the annulus. This compresses the gaseous phase and increases the downhole density of the circulating fluid.

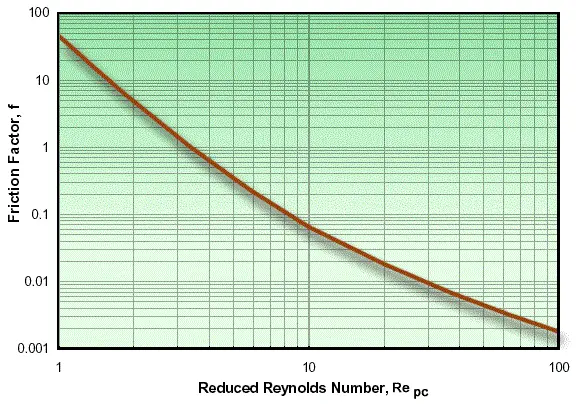

The correlation between friction factor and Reynolds Number is shown in the Figure 1.

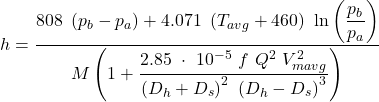

The air volume requirement as a function of bottomhole pressure and wellbore dimensions can be obtained by using this chart and the following equation which was developed by Poettmann and Bergman in 1955:

Equation 1

where:

M=42M.W+0.076 G ⋅ S

pb = desired bottomhole pressure, psia

pa = surface pressure, psia

Tavg = average temperature, oF

G = gas gravity

S = volume of gas (scf/bbl) of mud

M.W = mud weight, ppg

f = friction factor

Q = liquid flow rate, gpm

Vmavg = integrated average gas volume, ft3/bbl

Dh = wellbore diameter, in.

Ds = drillstring diameter, in.

A more rigorous method to predict bottomhole pressure during drilling in inclined borehole was presented by Sun et al. (2006).

The difference between static and flowing cases is considerably small. Therefore, the much simpler static analysis can be used to estimate the air flow rate. The fluid temperature does not have a big impact on the air volume requirement. The presence of cuttings in a borehole leads to a higher bottomhole pressure. However, most of the time this effect is small, and can be ignored when predicting circulating pressures.

For liquids, the circulating pressure calculation is straightforward. Standpipe pressure is simply the summation of the bottomhole pressure, the pressure drop at the bit, and the frictional pressure drops.

Compressibility of the gas phase makes it more complicated to predict the pressure drop of a gasified liquid.

Guo et al’s model (1993) can be used to make standpipe pressure predictions. Based on validation checks conducted on different wells, their model shows a deviation of 10% or less from the actual measurements.

The typical pressure behavior as a function of air rate is divided into two sections:

- Hydrostatic-dominated region (Region 1)

- Friction-dominated region (Region 2)

Figure 2 illustrates the effect of gas injection rate on bottomhole pressure.

In Region 1, bottomhole pressure is a strong function of gas injection rate. Therefore in this region the pressure is very sensitive to gas inflow from the formation into the annulus.

On the other hand, in the friction-dominated region, bottomhole pressure is not much affected by changes in gas injection rate. Thus, gas inflow does not have a significant effect on pressure. Therefore, it is recommended to design a circulating program that would fall into the friction-dominated region.

If inflow occurs, regardless of the type of inflow (gas or liquid), the gas/liquid injections should be adjusted to maintain the desired bottomhole pressure.

Knowledge about the flowing formation is necessary to properly balance a formation fluid inflow. It is possible to lose circulation at the bottom of the hole, while at the same time formation fluids flow in to a permeable zone up the hole.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.