Effect of Pump Rate and Equivalent Circulating Density on Displacement

Higher cement pumping rates create turbulent flow and tend to increase the efficiency with which cement displaces mud from the annular space. Cement must be pumped fast enough for it to scour mud from the side of the wellbore instead of merely flowing past the mudcake. However, increased pump rates mean increased pressure and care must be taken to understand what the impact of these higher rates will be on downhole pressures.

Equivalent circulating density (ECD) is the effective density of the circulating fluid (in this case cement) in the wellbore resulting from the sum of the pressure exerted by the hydrostatic head of the static column of cement (based on its density) and the friction pressure losses in the annulus when the cement is being pumped. This is commonly expressed in pounds per gallon ![]() .

.

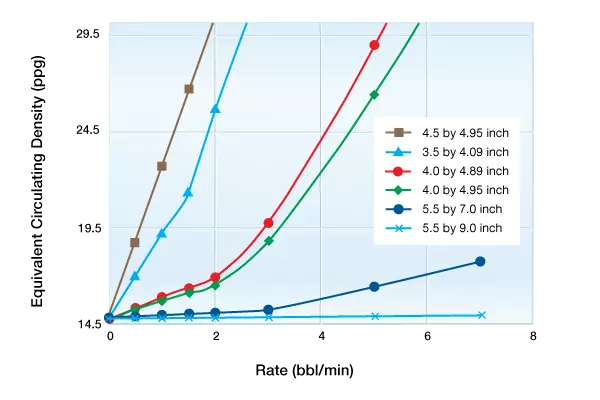

A modeling program can determine the dynamic annular pressures and ECD under various pump rates for various casing/wellbore combinations for a slurry with the following characteristics:

14.8 ![]() Class C slurry with fluid loss and dispersant additives

Class C slurry with fluid loss and dispersant additives

30.5 cp plastic viscosity

0.1 ![]() sq ft yield point

sq ft yield point

Figure 1 illustrates that increasing the pump rate from 2 ![]() to 5

to 5 ![]() in 1000 feet of annular space between a 5.5 inch OD casing string and a 7 inch wellbore will result in a 9% increase in ECD compared with the static column (16.1

in 1000 feet of annular space between a 5.5 inch OD casing string and a 7 inch wellbore will result in a 9% increase in ECD compared with the static column (16.1 ![]() versus 14.8

versus 14.8 ![]() ). The same increase in pump rate will result in a 70% pressure increase in a 4.0 inch casing in 4.89 inch open hole. Rates above 2

). The same increase in pump rate will result in a 70% pressure increase in a 4.0 inch casing in 4.89 inch open hole. Rates above 2 ![]() may more than double the annular pressures in smaller annular gaps. At the same time, for 5.5 inch OD casing run in a 9 inch hole, where the annular space is 1.75 inches, the added friction pressure is insignificant compared to the hydrostatic head.

may more than double the annular pressures in smaller annular gaps. At the same time, for 5.5 inch OD casing run in a 9 inch hole, where the annular space is 1.75 inches, the added friction pressure is insignificant compared to the hydrostatic head.

This information is important in choosing a pump rate that will be fast enough to scour the annulus but not so fast that it will increase the effective circulating density, and thus the bottomhole pressure at the casing shoe, to a level that will fracture the formation and lead to lost circulation.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.