Learning Objectives

After completing this topic “Introduction to Core Analysis“, you will be able to:

- Summarize the major types of core analysis.

- Discuss how core plugs from both consolidated and unconsolidated formations are analyzed.

- Summarize the overall processes of full diameter core analysis.

- Describe how rotary and percussion sidewall cores are analyzed in the laboratory.

Overview of Core Analysis

Core Samples

Core samples (Figure 1) are sections of whole rock extracted from a geological formation of particular interest to geoscientists and engineers. The acquisition of core material (Figure 2) from the potentially hydrocarbon-bearing reservoir, and the subsequent analyses of this core, are important activities in each of the exploration, appraisal, and development phases of the upstream field development process. A rock core provides the geoscientists and engineers with a direct means to measure the physical properties of sedimentary rocks so as to improve their understanding of the reservoir and better predict its hydrocarbon production performance.

Core analysis refers to a range of laboratory test procedures and data analyses of core samples. A variety of important information and data may be obtained through measurements and evaluation of the core sample’s physical and chemical properties, visual observations, and photographs under a variety of controlled conditions.

The two major categories of core analysis are “routine core analysis” and “special core analysis” (SCAL), each with their associated complementary data outputs.

Routine core analysis normally provides the following basic information about subsurface formations:

- Presence or absence of hydrocarbons

- Storage capacity (porosity)

- Flow capacity (permeability)

- Lithology, texture, and compositional elements of rock formations

- Rock grain density

- Hydrocarbon and water saturations

Laboratories for analyzing core samples are usually available locally so that these data, and any complementary measurements made after the well operator requests studies, can be made available within a few days of a core being recovered.

Special core analysis (SCAL) tests are more complex, and the data acquired are of wider diversity than the routine core analysis. Typically, SCAL requires considerably longer core preparation and testing times, and more specialized and expensive equipment. Large quantities of data are generated by the more sophisticated tests, especially when multiple cores are acquired on a well, or project. This increased time factor should be accounted for in project planning. SCAL includes both static and dynamic measurements, and usually establishes the following attributes of the formation:

- Flow properties of fluids when multiple phases are present

- Relative permeability

- Wettability

- Capillary pressure

- Electrical properties and associated empirical constants which are critical for conducting reliable well log interpretations

When cores are removed from the reservoir environment, they are normally subjected to reductions in pressure and temperature as they are brought to the surface. This changes the bulk and pore volume, reservoir fluid saturations, and in some cases the reservoir wettability (the preference of the rock for either water or oil). The effect of these changes depends on the reservoir depth, pressure and temperature, the rock, coring mud and reservoir fluid characteristics as well as the particular rock property being investigated. In many of the SCAL test procedures, both the pressure and temperature changes are important, and laboratory equipment and techniques are usually designed to simulate reservoir conditions downhole.

Full Diameter Cores

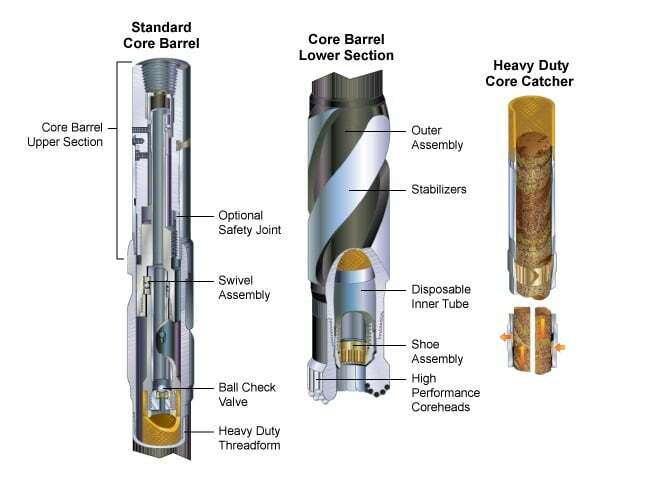

Full diameter cores (generally from 1.5 inches [3.8 cm] to 5.25 inches [13.3 cm] in diameter) are acquired by a core bit (Figure 3), which is located at the extreme lower end of the drill string, and a core barrel, (Figure 4), for retaining the core after it has been cut, which is positioned immediately above the core bit.

The core barrel normally consists of two main parts: a core-retaining inner barrel and a protective outer barrel (Figure 5). Both are usually approximately 30 ft long. Up to three barrel “joints” may be combined to allow a 90 ft. long core to be cut with a traditional drilling rig equipped with a kelly and rotary table system. The kelly is a long square or hexagonal steel bar with a hole drilled through the middle to allow fluid conduit.

The kelly transmits rotary motion from the rotary table or kelly bushing to the drill string, while allowing the drill string to be lowered or raised during rotation.

Some rigs are fitted with a top drive system which can drill 60 to 90 foot (18 to 27 m) stands (“doubles” or “triples” respectively—a triple being three joints of drill pipe screwed together, a double being two joints). Conventional full diameter cores can be successfully cut with either drilling system.

Sidewall Cores

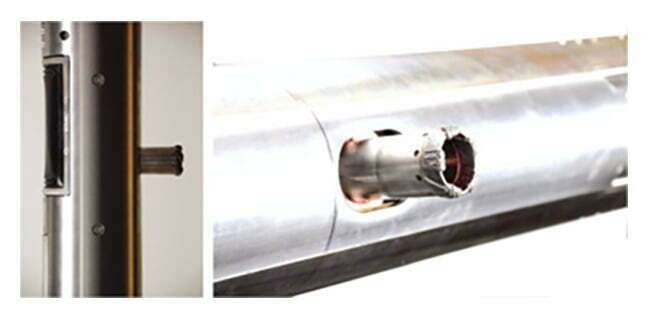

Sidewall cores can be subdivided into those acquired by percussion tools, as shown in Animation 1, and those obtained with a rotary sidewall coring bit, as shown in Figure 6. The latest technology rotary sidewall cores measure from 1.75 inches (4.5 cm) to 3.5 inches (8.9 cm) in length with a diameter from 1 inch (2.5 cm) to 1.5 inches (3.8 cm). This size is very similar to the dimensions of core plugs typically taken from conventional full diameter cores. The size of the rotary sidewall core samples and the number of sidewall samples which can be acquired in a single run into the wellbore vary among the different service companies.

Although plugs from full diameter cores can be sampled both perpendicular and parallel to the rock’s bedding planes so as to characterize the anisotropic rock properties and provide directional data for numerical simulation, the plug analysis described in this course is similar for both plugs cut from full diameter cores and samples acquired by rotary sidewall coring.

Percussion sidewall coring tool

In summary, this course provides an introductory overview of the major categories of core analysis:

- Core plug analysis

- Full diameter core analysis

- Rotary and percussion sidewall core analysis

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.