Treatment Materials and Procedures

Laboratory test data may also be important in the design of a fracture acidizing treatment. These data may be gathered from fluid-loss tests, acid reaction rate measurement, and acid etching tests.

Fluid-Loss Tests: Fluid-loss tests should be run on cores to determine how much fluid-loss additive is needed. The fluid-loss coefficients are necessary to calculate created fracture geometry in computer designs.

Acid Reaction Rate Measurement: An acid’s surface reaction rate can be determined on a formation core with a rotating core disc in a reaction cell to determine the penetration distance of live acid in a fracture. If no cores are available, generalized data obtained from typical limestone and dolomite formations can be substituted.

Acid Etching Tests: These very important laboratory tests help determine if fracture conductivity can be created by acid solutions, and which acids etch best. They also measure conductivity and the injection time required to obtain adequate conductivity. To calculate the productivity increase resulting from a treatment, first determine the fracture conductivity.

Types of Fracture Acidizing Treatments

There are several basic concepts to remember when considering types of acidizing treatments:

- Any pumped fluid follows the easiest route.

- A hole cannot be dissolved without leakoff. For example, 1000 gal of 15% HCl dissolves 10.8 cu ft(80 gal) of limestone but occupies 135 cu ft.

- The higher the permeability and the solubility, the greater the leakoff.

- Low-viscosity acids leak off more than high-viscosity acids.

- If the leakoff is less than the injected amount, a fracture will be created.

- Acid flows down a fracture easier than into the adjoining matrix.

- Acid spends faster in a small hole than in a big hole, or faster in a narrow fracture than in a wide fracture.

- Low-viscosity acid spends faster than high-viscosity acid.

- A 90% soluble rock is 10% insoluble, which will produce approximately

15% HCl.

15% HCl.

A number of fracture acidizing treatments types are available, each with advantages and disadvantages. Some of the common treatments are described below: conventional treatments, foamed acids, combination treatments, and preflushes.

Conventional Treatments: Conventional treatments run with low-viscosity acid are easy to perform. They tend to obtain high fracture flow capacity because of the narrow fracture and turbulent flow that develop. These treatments require less acid than most others and the acid may be chemically retarded.

These advantages are balanced by comparable disadvantages. The acid reacts rapidly in narrow fractures, but spends so quickly that deep penetration of the live acid is difficult. Low-viscosity acid does little to aid in fluid-loss control, and its fines-carrying capacity is limited.

Conventional fracture acidizing with high-viscosity acid overcomes most of the problems of low-viscosity acid, but has other disadvantages.

Advantages include easy mixing and pumping, good fluid-loss control, and better fines-carrying capacity. High-viscosity fracture acidizing treatments may use either gelled or emulsified acids. Gelled acids are more effective in friction reduction. A high-viscosity treatment is a retarded fracturing fluid system which develops a wider fracture, helps establish laminar flow within the fracture, and has a physical surface retarding effect.

Disadvantages of high-viscosity acid treatments are their high cost and possible problems of emulsion and lower fracture flow.

Foamed Acid: In addition to emulsified or gelled acids, foamed acid may be used in fracture acidizing treatments. Foamed acid has an erosive or scouring effect on the face of the fracture which helps develop good fracture flow capacity close to the wellbore. The fluids are easy to recover, even in low-pressure wells. The foam is good for removing fines and controlling fluid loss when used in low-permeability formations.

In spite of these advantages, foamed acid spends too fast to achieve deep penetration. More pressure is required at the surface to pump it. Foamed acid has considerable fluid-loss control capabilities, but it is more expensive than fluid-loss additives.

Combination Treatments: It is possible to run variations and combinations of the previously described types of treatments. An alternating-phase method called the “alpha” technique uses phases of acid (to improve fluid flow capacity) alternated with nonacid phases that contain fluid-loss additives. These non-acid phases also act as acid extenders, thus reducing the volume of acid required. The phases are normally alternated in 10- to 60-minute time frames, depending on specific situations.

The density-controlled acidizing technique uses the overriding and underriding characteristics of fluids with different densities, which are pumped in sequence into vertical fractures. This system uses less acid than others, and keeps acid out of unwanted zones because of viscosity differences.

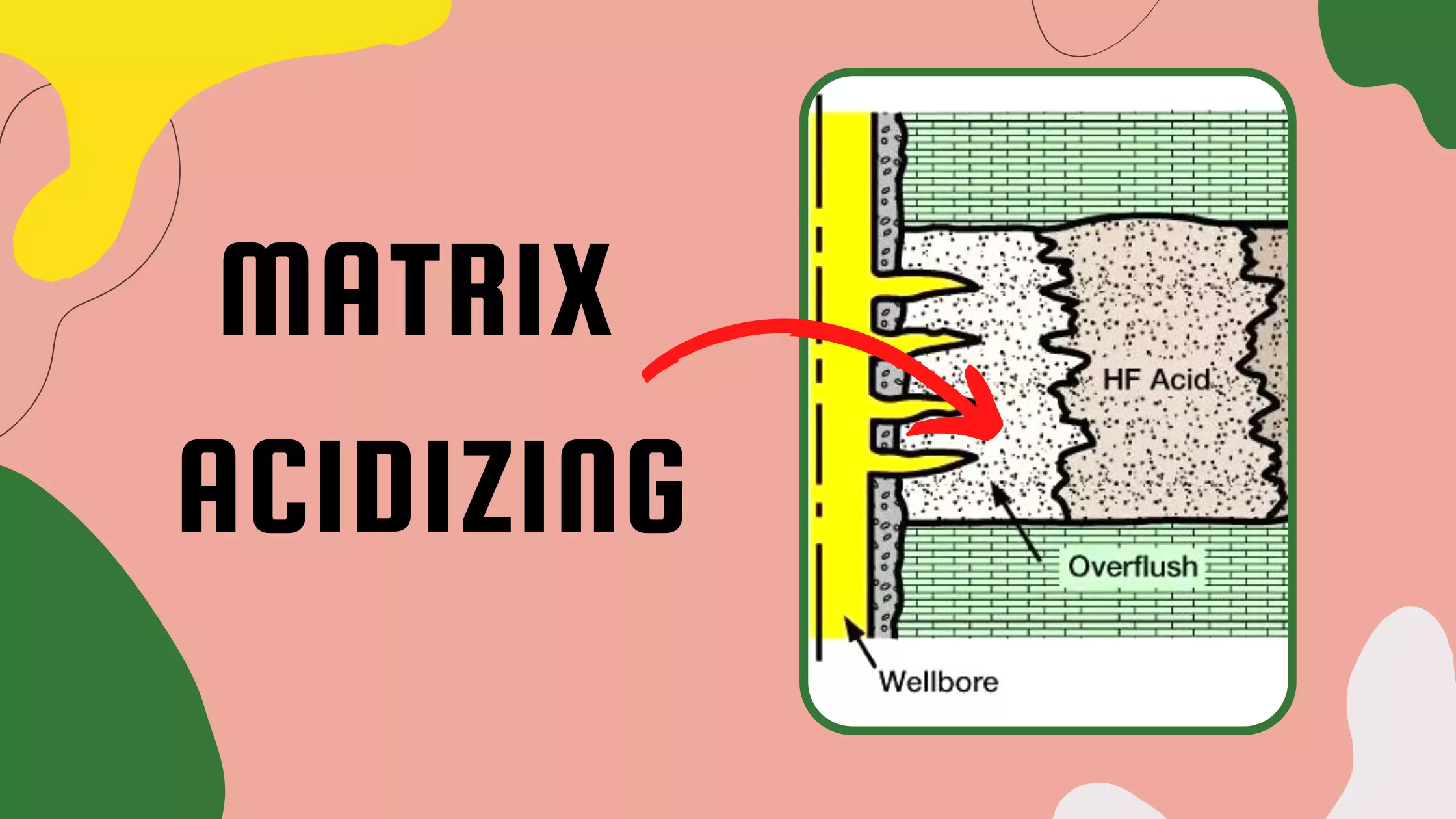

When standard fracture acidizing systems do not work, or cannot be run, systems called extended matrix acidizing and closed-fracture acidizing may be employed. Although calculations cannot be made regarding their acid penetration into wormholes or natural fractures, extended matrix acidizing does allow the acid, at less than fracturing pressure, to enter natural fractures and the area of highest permeability and solubility.

In closed-fracture acidizing, the “easy way out” routes for the acid are created fractures that have been allowed to close, and previously etched fractures that are closed.

When matrix acidizing is used, the acid generally goes out the area of highest permeability because there is less resistance to flow. It also goes out the areas of highest solubility because there are less fines released to act as fluid-loss control additives. It goes out natural fractures which have high solubility because they channel more readily.

Preflushes: Closed fracture acidizing can use a preflush to create a fracture rather than relying on a natural fracture system. The procedure is to create the fracture system by pumping a high-rate preflush, and then allow the fracture to close. Then, acid is pumped at below fracturing pressure through perforations into the closed fracture.

A previously etched closed fracture treatment is identical to the above, except the initial fracture is made with acid rather than with a preflush.

When preflushes are pumped before the treating phase, the treatment becomes more complex, more acid is required, and the cost goes up. However, the returns from this type of treatment are better fluid-loss control, and deeper penetration of live acid. An excellent acid-retarding system is introduced. Also, uneven etching is achieved mechanically, and unetched areas are able to support over-etched or acid-softened formation faces.

A preflush may be any fluid compatible with the treating phase that serves these intended purposes:

- creating the main fracture system prior to the acid phase

- controlling fluid loss ahead of the acid phase

- cooling the fracture face for longer acid reaction

- controlling density for optimum acid placement

A high-viscosity preflush can also

- create a wider fracture, for an acid-retarding effect

- allow the acid to channel, for a fingering effect

- control natural fracture leakoff more effectively

Overflush fluids are those generally pumped after the treating phase. These can be any compatible fluid that

- forces the acid out farther into the formation

- carries an energized fluid, such as nitrogen or CO2, for easier fluid recovery

- aids in the recovery of fines, if the fluid has sufficient viscosity

Treatment Design

The usual fracture acidizing design uses a computer to calculate the volumes of fluid necessary to obtain precise fracture geometry and productivity increases. The following discussion, which relates to fracture acidizing computer models, describes outputs, fracture conductivity, and inputs.

Outputs A fracture acidizing treatment creates conductivity by using acid to etch the walls of the created fracture. Thus a treatment design program must keep track of acid spending-how the acid reacts with the fracture walls – by providing several pieces of data:

- penetration distances

- amount of viscous fingering

- viscosity of stages

- acid velocities

- temperatures

- acid concentrations

- etched fracture length

Fracture Conductivity A fracture acidizing treatment must create a conductive fracture that increases well production. Fracture conductivity results directly from the etching process. The conductivity at a given point in the fracture is a function of the reactivity of the acid passing that point and the contact time between the acid and the fracture at that point.

Intuitively, it would seem that the longer the acid has contacted a portion of the fracture, the more material it will have removed and the greater the conductivity will be. If so, the greatest conductivity should be next to the wellbore where acid has contacted the formation the longest. This may be far from true, since fluid temperature is usually lowest as it enters the fracture and, if cool enough, the acid reacts very slowly and does very little etching there. As it penetrates farther into the fracture the acid becomes warm, increasing in effectiveness while it still has sufficient strength. The net result may be low fracture conductivity next to the wellbore and near the etched length, with possibly much higher conductivity somewhere in-between.

Any production increase calculations made in conjunction with a fracture acidizing program must consider this great conductivity variation along the fracture length. A single steady-state productivity index ratio cannot be effectively calculated.

Calculating production using a type curve simulator is difficult. Numerical simulators, however, readily lend themselves to this type of calculation.

Inputs: Fracture acidizing design programs require the input of formation properties

- fluid properties

- an estimated fracture height

- the pay zone location or height

They also require information about whether the treatment:

- is conventional

- uses the viscous fingering technique

- uses foamed acid

- uses any other special technique

Along with the treatment type, the acid type must also be selected and the acid concentration entered.

Acid type and concentration alone do not set the reaction kinetics. The other reaction component must be considered: the rock. If laboratory-generated reaction-rate data are available for the specific formation, these are usually entered into the computer program. If not, the program can empirically calculate reaction rate constants from rock-composition (dolomite or limestone) data. The program also requires data about

- well configuration

- injection rate

- proposed treatment designs

Treating Techniques

After selecting the type of acid and additives and using a computer design to help choose the quantity of preflush, viscous preflush, acid, and overflush, the number of stages must be determined. An estimate must be made of the expected vertical fracture height, given the injection rate, viscosity, rock properties, and changes in rock composition above and below the perforated interval.

Consider the apparent viscosity of the fluids in the treatment design. If the perforated interval appreciably exceeds the expected vertical fracture height, then a multiple-stage treatment is necessary. Of course, injection surveys, such as temperatures surveys and radioactive surveys, may be useful in obtaining accurate fracture height information after a treatment. This data can then be used for planning similar fracture acidizing treatments in the future. Mechanical diversion or use of diverting materials may be required to obtain the most effective zonal coverage.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.