Composition of Injected Liquid

The injected liquid is composed of water, a foaming agent and a corrosion inhibitor. Hole conditions and the interaction of the foaming agent with the formation fluids determine the concentration of the foaming agent to be injected. Typical concentrations range from 0.5 to 2 percent.

Almost all surfactants used as foaming agents are bio-degradable. Contamination of the drilling liquid by formation fluids or by a chemical defoamer can cause disposal problems, even if the foaming agent itself is environmentally acceptable.

Defoaming is achieved by either chemical or mechanical means. Spraying a suitable defoamer in the return pit helps to destroy the foam at a much faster rate. More effective results can be obtained if the defoamer is mixed thoroughly with the returning foam by injecting the defoamer into the blooie line using a ring spray. In order to obtain effective defoaming it is important to match the foaming agent being used with the proper defoamer.

Recommended for You Nitrogen Drilling

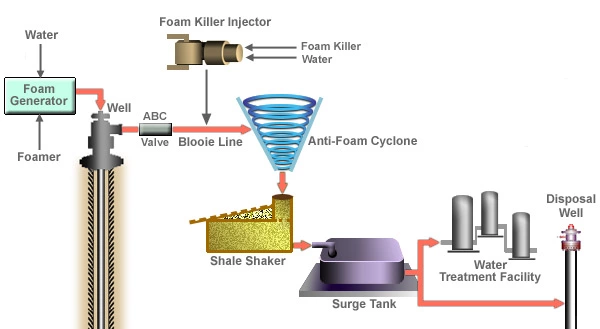

The main principle of mechanical foam breaking is based on gravity-induced separation of the foam’s liquid and gaseous phases. A hydro-cyclone in conjunction with a chemical defoamer is a successful technique used in field applications as shown in Figure 1. Other types of mechanical defoaming techniques are the use of a spinning drum and corkscrew-like internal flow paths.

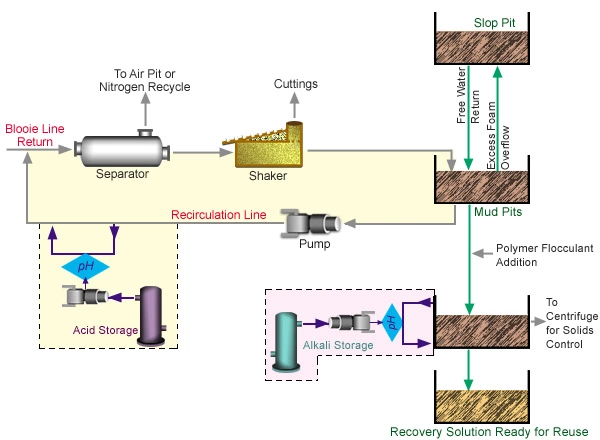

A newer technique destroys the foam by changing its pH. Acid is injected at the blooie line, reducing the pH and eventually destabilizing the foam. The treated foam is then separated and recycled into the well after passing over a shale shaker and through an additional pH adjustment. The surface equipment needed for this operation is shown in Figure 2.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.