Heavy Wall Drill Pipe

Heavy wall drill pipe (Figure 1) is an intermediate drill string member — heavier, stronger and stiffer than regular drill pipe, but at the same time more flexible than drill collars.

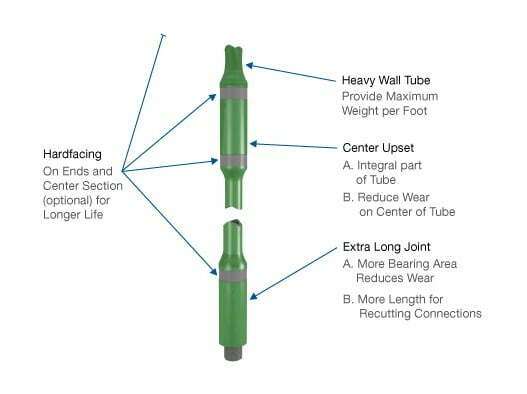

Because it has the same external dimensions as regular drill pipe, it is much easier to handle than drill collars. Figure 2 illustrates some of its important features.

The most important drill string application for heavy wall drill pipe is in the area above the topmost drill collars where drill pipe fatigue failure is most likely to occur. To reduce fatigue failures in this area of the borehole, 18 to 21 joints of heavy wall drill pipe may be run above the drill collars. This provides a gradual change in stiffness between drill collars and drill pipe. Also, the ability of the heavy wall drill pipe to bend (unlike drill collars) serves to relieve high stresses at the connections.

To prevent too great a change in stiffness between the drill collars and the heavy wall drill pipe, the guidelines below can be used.

| Heavy Wall Drill Pipe OD (inches ) | Maximum Drill Collar OD (inches) |

|---|---|

| 3.50 | 6.00 |

| 4.00 | 6.50 |

| 4.50 | 7.25 |

| 5.00 | 8.25 |

Heavy wall drill pipe was first used in directional drilling, which generally requires flexibility in the drill string. It is now widely used in vertical and horizontal drilling as well. With less wall contact than would be experienced with drill collars, its usage reduces torque and wall-sticking tendencies. Its smaller degree of wall contact, together with its greater stiffness relative to regular drill pipe, results in increased stability and better directional control. Heavy wall drill pipe is also useful in reducing hook loads, making it ideal for smaller rigs drilling deeper holes.

In certain special applications (most notably horizontal drilling) heavy wall drill pipe may be run in compression. It is important to keep in mind, however, that a joint of heavy wall drill pipe is not as strong as a drill collar, and that it is still susceptible to buckling and fatigue failure. In a vertical hole, heavy wall drill pipe must be maintained in tension.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.