Temperature Surveys

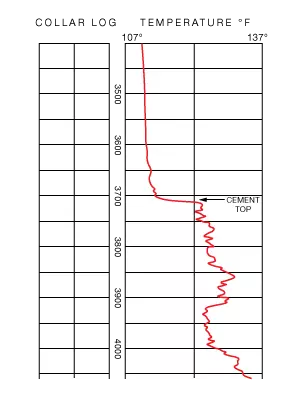

When cement hydrates, the exothermic chemical reaction significantly increases the temperature of the surrounding material and in some cases this temperature increase can be observed as a function of depth with a temperature log (Figure 1).

This type of log can be used to estimate the top-of-cement (TOC) in the annulus behind pipe. This estimate for TOC, together with an accurately callipered hole size, casing size, and volume of cement pumped, will allow a completion engineer to estimate the displacement efficiency of the mud behind pipe and thus a relative assessment of the likelihood of effective hydraulic isolation.

The maximum temperature change resulting from cement hydration ranges from about 10° to 40 °F. The magnitude of the difference detectable by a temperature log depends on these factors:

- Thickness of the annulus

- Thermal conductivity of the formation

- Percentage of cement in the slurry mixture

- Amount of circulation done before and during cementing

Low-density cements with extenders generate less heat per unit volume and the temperature increase may be too small to detect.

In most cases the peak temperature increase will occur 4 to 12 hours after cement placement, but the temperature may remain elevated for more than 24 hours. A temperature survey should be run within 12 to 24 hours after cement placement for best results, depending on thickening time and downhole conditions.

Temperature surveys are not common because more sophisticated and accurate tools are required to understand the quality of the cement job as well as where the top of the cement has reached.

Radioactive Tracer Surveys

A radioactive tracer survey is typically used to evaluate gravel packs and identify lost circulation zones, and can occasionally be used to evaluate a primary cement job, but this is rare. Short half-life radioactive tracers are added to cement slurry so that a post-cementing radioactive logging survey can be used to identify the top-of-cement (TOC).

Challenges and Limitations of Cement Evaluation Well Logging:

While cement evaluation well logging is a valuable technique for assessing the quality of cement in oil and gas wells, it does come with some challenges and limitations. Understanding these challenges is essential for accurate interpretation and effective decision-making. Here are the key challenges and limitations:

- Variable Formation Properties: The formation properties surrounding the wellbore can vary significantly, making it challenging to establish universal criteria for evaluating cement integrity. Different formations may have different natural radioactivity levels or acoustic properties, requiring careful interpretation and calibration.

- Tool Limitations: Different logging tools have specific limitations that can impact the accuracy and reliability of cement evaluation. Factors such as tool size, sensitivity, and positioning within the wellbore can influence the measurements and potentially lead to uncertainties in the results.

- Cement Composition Variations: Cement composition can vary due to factors such as additives, curing time, and temperature. These variations can affect the response of logging tools, making it necessary to consider cement composition when interpreting the results.

- Wellbore Conditions: Wellbore conditions, such as mud invasion, rugosity (roughness), or irregular casing surfaces, can affect the reliability of cement evaluation logs. These conditions may result in poor tool coupling or interference, leading to inaccurate measurements and challenges in assessing cement quality.

- Cement Sheath Thickness: The thickness of the cement sheath can impact the interpretation of cement evaluation logs. In cases where the cement sheath is thin or has variations in thickness, it may be difficult to distinguish between bonding issues and natural variations in the formation properties.

- Limited Spatial Resolution: Some logging tools may have limited spatial resolution, making it challenging to identify small-scale bonding issues or thin micro-annuli. These issues can potentially go undetected, requiring additional techniques or higher-resolution tools for accurate assessment.

- Interpretation Expertise: Proper interpretation of cement evaluation logs requires expertise and experience. Analyzing the data and distinguishing between bonding issues and natural variations can be complex, and inexperienced interpretation can lead to misinterpretations or inaccurate assessments.

- Data Integration: Cement evaluation well logging provides valuable information, but it is most effective when integrated with other data sources, such as cementing job parameters, drilling records, and wellbore geology. Integrating multiple data sets helps in comprehensive evaluation and accurate assessment of cement quality.

Despite these challenges and limitations, cement evaluation well logging remains a vital technique for evaluating cement integrity. By understanding these limitations and considering them during the interpretation process, engineers can enhance the accuracy and reliability of the assessment and make informed decisions regarding wellbore integrity and remedial actions.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.