Learning Objectives

After completing this topic “Diverting Materials in Acidizing“, you will be able answer to:

- What is acidizing process?

- What is acidizing in drilling?

- What is matrix stimulation?

- What is the difference between hydraulic fracturing and acidizing?

- What are the differences between matrix acidizing and fracture acidizing?

- Which acid is used in acidizing process?

- What is iron control agent?

- How is HCl used in fracking?

- What is SandStone acidizing?

- What is in hydrochloric acid?

- What is stimulation in oil and gas?

- What is acid job in oil industry?

- How do you make hydrofluoric acid?

- What are the objectives of matrix stimulation?

- What is the purpose of using additives in acidizing process for oil well?

- What are acid additives?

- Diverting Materials in Acidizing

- Selection of Diverters

By completing this topic and then applying the learnings in your job, you will be able to attain Basic Application Competence Level in Acidizing and Other Chemical Treatments.

Introduction

To obtain maximum stimulation from a matrix or fracturing acidizing treatment, it is necessary to treat the total productive interval. When several zones are open to the wellbore, or when the section to be treated is massive, it is often necessary to divide the treatment into stages. A technique that forces each stage to go into a different zone ensures treatment of the total productive interval.

In the case of multiple intervals, the formations may differ from one another in reservoir pressure as well as permeability. Flow often can be effectively diverted using downhole equipment such as packers and bridge plugs, and sliding sleeves between packers. However, since use of a workover rig to move downhole equipment can significantly increase total cost, techniques for separting the treatment into stages without using packers are often preferred These techniques, which use a diverting material, temporarily plug the interval just treated, thereby diverting the next acid stage to an untreated zone.

Diverting can be achieved completions like openhole zones, gravel-packed zones, and perforations by varying the diverting material size distribution.

Solid Diverters

The most widely used method of placing treating fluids employs diverting agents composed of solid particles. The particles create a restriction in and across the formation sections that accept fluid most readily, forcing the breakdown of other exposed intervals. Ideal solid-type diverting agent properties

- have a wide particle-size distribution

– coarse: 0.25 to 0.002 in.

– fine: 0.02 to 0.0001 in. - are soluble in both water and oil

- have a slow rate of solubility, so the agent remains solid during the entire stimulation treatment

- dissolve in a reasonable time, so the well can be returned to production or injection without unnecessary delay

- cause no damage to formation permeability

- are suitable for use with both perforations and in openhole

- block effectively across fractures and perforations at high differential pressures

- remain stable at high bottomhole temperatures

- are compatible with all well and treating fluids, including acid

More information about the physical and chemical properties of solid-type diverting materials follows.

Physical Properties: The melting point of the solids used in diverting should be sufficiently higher than the formation temperature so that the solid does not melt or soften on the formation face during the treatment. However, some solids depend on melting with reservoir temperature to be removed. The most important property of the diverting solids is their particle-size distribution. Diverting in all types of completions, except gravel-packed zones, requires a uniform particle-size distribution from 40-mesh to smaller than 325-mesh. This distribution provides sufficient variation in particle size to treat a wide range of varying permeabilities.

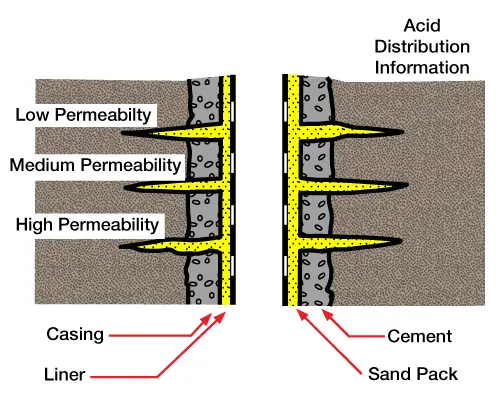

To divert through a gravel pack, the solid diverting material must be fine enough to penetrate the gravel pack and filter out on the formation face. Effectiveness of acid distribution with and without diverting agent is demonstrated by comparing Figure 1 (distribution of acid without diverting agent)and Figure 2 (distribution of acid with diverting agent).

If the diverter is not fine enough to penetrate the gravel pack, the material will bridge on the gravel. This diverts the fluids to a different portion of the gravel pack. However, fluid can then move vertically in the gravel pack so that all the acid is still flowing into the same highest-permeability zones. The low-permeability zones may remain untreated.

Chemical Properties: The diverting solids should have limited solubility in acid solutions. To aid in their removal after the acidizing treatment, however, the solids should be soluble in natural formation fluids, such as oil, gas, and connate water.

A material with limited solubility in water is useful for diverting acid in water wells or injection wells. In these situations, a sufficiently high volume of water flows through the diverted zone to eventually remove all the solid diverting material. These solid diverting agents should be compatible with surfactants, corrosion inhibitors, and mutual solvent additives in the acidizing fluids.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.