Drying Core Plugs and Sidewall Core Samples

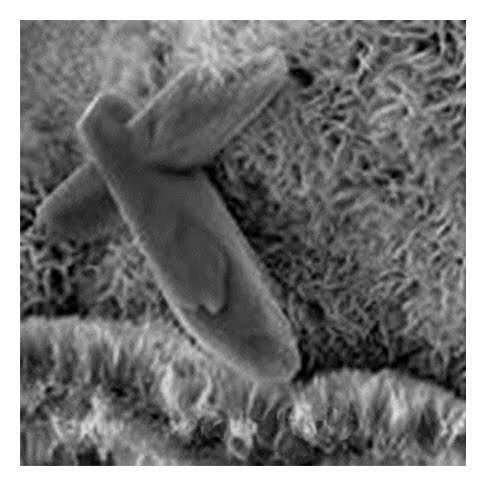

Drying poses no significant problems in most stable rocks, and temperatures of 240º F (115º C) can be maintained with no real damage to the core samples. Formations containing hydratable clays, as shown in Figure 1, can be dried in a humidity drying oven set at 45% relative humidity and 145° F (64° C). These conditions leave two molecular layers of water on the clay surfaces, an amount that clay chemists believe to be appropriate. Observation of samples taken from depths of 1000 ft (305 m) or less shows that some cores crack while in the humidity oven even under these conditions. This would indicate that more than two molecular layers are actually present on the clay surfaces at these lesser depths.

In the humidity drying technique, water bound to the sand grains reduces both the porosity and the grain density. Clay bearing samples subsequently dried in a regular oven will show both an increase in porosity and an increase in grain density (an example is given in Table 1). When interpreting core analysis data, it is always important to know which core analysis drying technique was used.

| Property | Property Oven dried @ 240° F | Humidity Dried @ 145° F and 45% relative humidity |

|---|---|---|

| Bulk volume, cm3 | 10.0 | 10.0 |

| Pore volume, cm3 | 2.6 | 2.27 |

| Porosity, % | 26.0 | 22.7 |

| Grain volume, cm3 | 7.4 | 7.73 |

| Dry weight, g | 19.61 | 19.94 |

| Grain density, g/cm3 | 2.65 | 2.58 |

High permeability samples can sometimes be dried within several hours, and this time framework can be reduced by the application of a vacuum to the samples as the heat is applied. As permeability decreases, the required drying time increases. In some cores, with permeabilities of less than one millidarcy, 48 hours have been required in non-vacuum ovens. As the sample size increases, the drying time increases. Unconsolidated rock samples enclosed within metal or plastic jackets will require longer drying times than those samples exposed on all surfaces.

Petro Shine The Place for Oil and Gas Professionals.

Petro Shine The Place for Oil and Gas Professionals.